Supercritical fluids exhibit distinctive characteristics that can greatly enhance textile processing by offering an effective alternative to water in dyeing applications. Supercritical carbon dioxide, in particular, combines the solvating abilities of liquid solvents with the low viscosity and high diffusion rates of gases, making it an ideal and environmentally friendly solvent for modern manufacturing. Utilizing Supercritical carbon dioxide in commercial textile processes is anticipated to provide numerous advantages over traditional aqueous methods, such as eliminating wastewater production, lowering energy usage, reducing drying times, and curtailing air pollution. As a result, Supercritical carbon dioxide is expected to make textile processing more cost-effective and ecologically sustainable. Research initiatives worldwide are investigating the potential of Supercritical carbon dioxide in textile applications, with several pilot dyeing systems successfully implemented and publicly demonstrated in recent years. A notable example is a six-year research project at North Carolina State University’s College of Textiles focused on developing a commercial dyeing method for polyester yarn packages. This initiative utilizes a single-package Supercritical carbon dioxide dyeing machine located within the College’s Model Manufacturing Facility. This paper presents a comprehensive overview of the current state of this research, emphasizing the technical and economic considerations crucial for the successful commercialization of Supercritical carbon dioxide dyeing technologies for polyester yarn.

The supercritical state, often regarded as the fourth state of matter, plays a pivotal role in advancing various manufacturing processes, particularly in the textile industry. Defined as the condition where a substance exists at temperatures and pressures beyond its critical point, the supercritical state is characterized by unique properties that blend the features of both liquids and gases [1]. As substances approach their critical points, they exhibit a remarkable increase in density, leading to enhanced solvent capabilities while maintaining relatively low viscosity and high diffusivity. These characteristics enable supercritical fluids to facilitate superior mass transfer and efficiency in processing applications [2].

Among the various supercritical fluids, supercritical carbon dioxide (Supercritical carbon dioxide) stands out as a leading candidate for industrial use [3]. Its affordability, non-toxic nature, non-flammability, and environmental compatibility, coupled with its accessible critical parameters (73.8 bar, 31.1 °C), make Supercritical carbon dioxide particularly attractive for manufacturing applications. The successful implementation of Supercritical carbon dioxide in various sectors has sparked considerable interest in its application within textile processing, especially in dyeing methods.

A review of the technical literature indicates a substantial increase in research and development focused on Supercritical carbon dioxide dyeing over the past decade, with an exponential rise in publications reflecting this growing interest. Furthermore, the steady growth in the number of patents issued in this area signifies a robust momentum towards commercializing Supercritical carbon dioxide dyeing processes [4]. Notably, much of this research has concentrated on the dyeing of polyester materials, particularly yarn packages. This introduction sets the stage for a comprehensive exploration of the advancements and challenges associated with Supercritical carbon dioxide dyeing, emphasizing its potential to revolutionize textile processing through enhanced economic and environmental benefits.

The textile industry has long faced challenges associated with traditional dyeing methods, particularly concerning environmental impact and resource consumption. Conventional aqueous dyeing processes often result in significant wastewater production, high energy requirements for drying, and the potential for air emissions that can harm both human health and the environment [5-7]. The advent of Supercritical carbon dioxide dyeing presents a promising solution to these issues, offering a more sustainable approach that aligns with contemporary environmental standards.

Supercritical carbon dioxide dyeing eliminates the need for water, thereby reducing the generation of wastewater and the associated costs of treatment and disposal. Additionally, the low viscosity of supercritical carbon dioxide allows for easier pumping and manipulation, leading to energy savings during processing. The increased mass transfer rates facilitated by Supercritical carbon dioxide enhance dye uptake, resulting in more uniform and vibrant color application on textiles. As a result, this method not only improves dyeing efficiency but also expands the potential for innovative dye formulations and applications [4].

Despite its numerous advantages, the transition to Supercritical carbon dioxide dyeing is not without challenges. The complexities involved in adapting existing dyeing equipment to accommodate supercritical conditions, as well as the need for tailored dye formulations that work effectively in a carbon dioxide medium, are areas of ongoing research and development. Furthermore, understanding the economic implications of scaling up Supercritical carbon dioxide dyeing processes for widespread commercial use remains a crucial aspect of this evolving field [8].

In summary, the exploration of supercritical carbon dioxide dyeing represents a significant leap forward in textile processing, with the potential to address longstanding environmental and economic challenges. As research continues to advance, the focus on optimizing Supercritical carbon dioxide systems for various textile applications will be essential in paving the way for a more sustainable future in the textile industry.

Research on the application of supercritical carbon dioxide (Supercritical carbon dioxide) dyeing has increasingly focused on polyester yarn packages, as indicated by the significant interest reflected in the technical literature over the past decade. This interest is predominantly attributed to the unique benefits Supercritical carbon dioxide offers compared to traditional aqueous dyeing methods. A comparison of conventional dyeing processes with Supercritical carbon dioxide dyeing reveals numerous advantages, particularly the elimination of water usage, which in turn eradicates the need for wastewater treatment. Additionally, dyeing times are considerably reduced, leading to enhanced productivity since drying processes are unnecessary. This results in the elimination of dryer effluent, further contributing to environmental benefits.

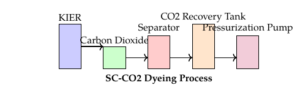

In the Supercritical carbon dioxide dyeing process, pure presscake disperse dyes are employed, eliminating the surfactants and chemical auxiliaries commonly found in commercial disperse dyes. The dye utilization rates in Supercritical carbon dioxide dyeing are remarkably high, often exceeding 99%, which means that the volume of unused dye exiting the process is minimal. Any residual dye is efficiently captured for potential reuse or safe disposal. Furthermore, the carbon dioxide utilized in the dyeing process is typically recycled at rates greater than 90%, reinforcing the sustainability of the method.

Substantial experimental activity has been conducted at both laboratory and pilot scales to facilitate the eventual commercialization of Supercritical carbon dioxide dyeing processes for polyester yarn packages. This research has progressed beyond laboratory-scale experiments to include pilot plant operations at various locations, as summarized in Table 2. This paper particularly emphasizes the commercialization efforts related to Supercritical carbon dioxide dyeing being undertaken within the College of Textiles, highlighting the advancements and innovations that support the transition to this environmentally friendly dyeing technology.

Experimental work on Supercritical carbon dioxide dyeing has involved systematic testing to assess the efficiency and effectiveness of the dyeing process. The pilot-scale setups have been designed to replicate industrial conditions, allowing for comprehensive evaluation of various parameters, including pressure, temperature, and dyeing time. The optimal conditions for dyeing polyester yarn packages have been determined through a series of experiments, focusing on achieving maximum dye uptake and color fastness.

In these studies, the yarn packages are subjected to Supercritical carbon dioxide at pressures exceeding 73.8 bar and temperatures around 31.1 °C, conditions that correspond to the critical point of carbon dioxide. During the dyeing process, the flow of supercritical carbon dioxide is carefully controlled to ensure consistent dyeing conditions. The presscake disperse dyes are introduced into the system, allowing the supercritical fluid to facilitate dye penetration into the yarn fibers effectively.

Dye uptake is measured through spectrophotometric analysis, which quantifies the color intensity on the dyed fabric. This allows for the calculation of dye utilization efficiency, confirming values often greater than 99%. Additionally, color fastness is evaluated using standardized tests, including washing and lightfastness assessments, to ensure the durability of the dye.

The environmental impact of the Supercritical carbon dioxide dyeing process is also evaluated by measuring the reduction in wastewater production and energy consumption compared to traditional aqueous methods. These assessments help to demonstrate the sustainability of the Supercritical carbon dioxide approach, further supporting its potential for commercialization.

Through collaborative efforts at the College of Textiles, this research aims to refine the Supercritical carbon dioxide dyeing process, addressing both technical and economic challenges to facilitate its adoption in the textile industry. The findings from these experiments will contribute to a comprehensive understanding of Supercritical carbon dioxide dyeing and its implications for a more sustainable future in textile processing.

The ongoing program to commercialize the supercritical carbon dioxide (Supercritical carbon dioxide) dyeing process for polyester yarn has successfully progressed into its sixth year, following its initiation in early 1996. A significant milestone was reached with the installation of a pilot Supercritical carbon dioxide dyeing machine in the College of Textiles’ Model Manufacturing Facility, where the first successful dyeing was accomplished in December 1996.

To date, over 500 process development trials have been conducted on the pilot machine, evaluating 20 different disperse dyes specifically for dyeing polyester yarn packages. The primary dyes tested include C.I. Disperse Red 167, C.I. Disperse Blue 77, and C.I. Disperse Blue 60. In many instances, combinations of three dyes were used to create a variety of shades. The trials predominantly utilized 1/150/34 filament polyester yarn, with additional experiments conducted on 43/2 spun polyester yarn.

The results from these trials demonstrated that the Supercritical carbon dioxide dyeing process provides excellent shade development, levelness, and satisfactory crocking resistance (both wet and dry). Notably, the physical properties of the yarns dyed using the Supercritical carbon dioxide process were found to be equivalent to those dyed by conventional aqueous methods.

Furthermore, the research included the successful application of ultraviolet (UV) absorbers on polyester yarn, achieved through both laboratory and pilot-scale testing. The yarns treated with Supercritical carbon dioxide exhibited good penetration of the UV absorbers, showing acceptable light fastness properties.

While the Supercritical carbon dioxide dyeing process presents numerous advantages, the production of trimer remains a significant challenge, mirroring issues faced in traditional aqueous dyeing systems. Although the trimer can be removed using conventional aqueous cleaning methods, the development of effective carbon dioxide-only cleaning procedures is still in progress. Despite advancements in understanding trimer formation in the Supercritical carbon dioxide dyeing process, a satisfactory carbon dioxide-only cleaning solution has yet to be established.

| Parameter | Value |

| Pressure | 73.8 bar |

| Temperature | 31.1 °C |

| Dyeing Time | Significantly reduced |

| Flow Rate | Similar to aqueous |

| Dye Utilization | Greater than 99% |

| CO2 Recycling Rate | Greater than 90% |

The exploration of supercritical carbon dioxide (Supercritical carbon dioxide) dyeing as an alternative to traditional aqueous dyeing processes presents a transformative approach for the textile industry, particularly in dyeing polyester yarn packages. This study marks significant advancements in the ongoing effort to commercialize Supercritical carbon dioxide dyeing technology, which began in 1996. The integration of Supercritical carbon dioxide into dyeing processes has been driven by the pressing need for sustainable practices that reduce environmental impact, lower resource consumption, and enhance productivity [1,2,6,7].

The unique properties of Supercritical carbon dioxide, including its liquid-like density combined with gas-like viscosity and diffusivity, facilitate effective dye penetration and interaction with polyester fibers. The over 500 trials conducted on the pilot Supercritical carbon dioxide dyeing machine reveal that this method not only eliminates water usage but also minimizes wastewater generation—a crucial advantage in today’s environmentally conscious landscape. The findings confirm that Supercritical carbon dioxide dyeing achieves dye utilization rates exceeding 99%, significantly reducing the volume of unused dye and allowing for potential reuse, thereby addressing both economic and ecological concerns [8].

One of the major outcomes of this research is the confirmation that yarns dyed with Supercritical carbon dioxide exhibit color characteristics and physical properties comparable to those dyed through conventional aqueous methods. The superior shade development and levelness achieved through Supercritical carbon dioxide dyeing demonstrate its capability to meet industry standards for quality while enhancing operational efficiency [5]. Moreover, the successful application of ultraviolet (UV) absorbers using Supercritical carbon dioxide further underscores the versatility of this method. The good penetration of UV absorbers and acceptable light fastness properties highlight the potential for Supercritical carbon dioxide in producing textiles that not only exhibit vibrant colors but also provide additional protective qualities [9].

However, the process is not without challenges. The formation of trimer during dyeing poses significant operational hurdles, similar to those encountered in traditional dyeing systems. While the current methods of trimer removal using aqueous cleaning techniques are effective, the search for carbon dioxide-only cleaning procedures remains a priority. The inability to establish a satisfactory method for trimer removal in a carbon dioxide environment indicates an area where further research is essential [10]. Understanding the mechanisms behind trimer formation in Supercritical carbon dioxide dyeing could lead to more efficient solutions that align with the sustainability goals of the process.

The commercialization efforts reported in this study highlight a promising trajectory for Supercritical carbon dioxide dyeing technology. The transition from laboratory-scale experimentation to pilot-scale application signifies the maturity of this research. With ongoing support from the College of Textiles, the refinement of Supercritical carbon dioxide dyeing processes is expected to continue, potentially leading to widespread adoption across the textile industry. Future work should focus on optimizing process parameters, enhancing dye formulations, and addressing remaining challenges such as trimer management [11,12].

In conclusion, the Supercritical carbon dioxide dyeing process represents a significant leap towards sustainable textile processing. By harnessing the unique properties of supercritical carbon dioxide, this method offers an innovative solution that can greatly reduce the environmental footprint of dyeing operations while maintaining high standards of quality and efficiency. Continued research and development in this area promise to unlock further applications and enhancements, solidifying Supercritical carbon dioxide dyeing as a viable alternative to conventional methods in the textile industry [12].

As the textile industry increasingly prioritizes sustainability, the development and optimization of Supercritical carbon dioxide dyeing technology could set new standards for eco-friendly practices. The successful implementation of this method not only aligns with global sustainability goals but also addresses consumer demand for environmentally responsible products. With heightened awareness regarding the environmental impacts of conventional dyeing processes, Supercritical carbon dioxide dyeing provides a compelling alternative that minimizes water usage and reduces harmful wastewater discharges.

Future research should focus on several key areas to enhance the viability of Supercritical carbon dioxide dyeing. First, expanding the range of dye types and formulations that are compatible with Supercritical carbon dioxide can improve the versatility of the process. Investigating alternative disperse dyes, including those derived from natural sources or designed to be more soluble in supercritical carbon dioxide, could open new markets and applications for this technology.

Second, developing innovative cleaning procedures that effectively manage trimer accumulation without the need for water is crucial. Research into enzymatic treatments or advanced filtration systems that can operate in supercritical environments may yield promising solutions. Moreover, understanding the reaction pathways and kinetics of trimer formation during dyeing can lead to strategies that mitigate its production, ultimately enhancing the operational efficiency of the dyeing process.

Additionally, as the Supercritical carbon dioxide dyeing process matures, scaling up from pilot to commercial operations will necessitate rigorous economic evaluations. Comprehensive cost-benefit analyses comparing Supercritical carbon dioxide dyeing with traditional methods will be essential for stakeholders. Factors such as initial investment costs, operational efficiencies, and long-term sustainability benefits must be quantified to support decision-making in the textile industry.

The collaboration between academia and industry will play a pivotal role in driving the successful commercialization of Supercritical carbon dioxide dyeing. Partnerships that leverage the expertise of research institutions with the practical insights of textile manufacturers can accelerate technology transfer and innovation. This synergy can facilitate the identification of best practices and the development of standardized procedures, further promoting the adoption of Supercritical carbon dioxide dyeing across the industry.

In summary, the potential impact of Supercritical carbon dioxide dyeing extends beyond mere technological advancements; it embodies a shift towards more sustainable manufacturing practices in textiles. By addressing environmental concerns while maintaining product quality, Supercritical carbon dioxide dyeing can contribute to a more sustainable future for the textile industry. As research and development efforts continue, the hope is that this innovative dyeing method will become a cornerstone of eco-friendly textile processing, leading to a significant reduction in the industry’s overall ecological footprint.

The advancement of supercritical carbon dioxide (Supercritical carbon dioxide) dyeing technology represents a significant step towards sustainable practices in the textile industry. This innovative approach not only eliminates water usage and reduces harmful wastewater discharges but also maintains high dye utilization and quality comparable to traditional methods. While challenges such as trimer management remain, ongoing research and development promise to address these issues and enhance the viability of Supercritical carbon dioxide dyeing for commercial applications. As the textile industry continues to seek environmentally responsible solutions, Supercritical carbon dioxide dyeing stands poised to play a pivotal role in reshaping the future of textile processing, aligning economic and ecological goals for a more sustainable production landscape.

Goni, Maria L., Nicolas A. Ganan, and Raquel E. Martini. “Supercritical CO2-assisted dyeing and functionalization of polymeric materials: A review of recent advances (2015–2020).” Journal of CO2 Utilization 54 (2021): 101760.

Banchero, Mauro. “Recent advances in supercritical fluid dyeing.” Coloration technology 136.4 (2020): 317-335.

Amenaghawon, Andrew N., et al. “Applications of supercritical carbon dioxide in textile industry.” Green Sustainable Process for Chemical and Environmental Engineering and Science. Elsevier, 2020. 329-346.

Banchero, Mauro. “Supercritical fluid dyeing of synthetic and natural textiles–a review.” Coloration Technology 129.1 (2013): 2-17.

Munshi, Pradip, and Sumit Bhaduri. “Supercritical CO 2: a twenty-first century solvent for the chemical industry.” Current Science (00113891) 97.1 (2009).

Franco, Paola, et al. “Supercritical carbon dioxide-based processes in photocatalytic applications.” Molecules 26.9 (2021): 2640.

Ratnapandian, Saminathan. “Natural colorants and its recent developments.” Sustainable technologies for fashion and textiles. Woodhead Publishing, 2020. 189-208.

Long, Jia-Jie, et al. “Clean fixation of dye on cotton in supercritical carbon dioxide with a heterogeneous and phase transfer catalytic reaction.” Dyes and Pigments 115 (2015): 88-95.

Liu, Ruixia, et al. “Ionic liquids and supercritical carbon dioxide: green and alternative reaction media for chemical processes.” Reviews in Chemical Engineering 32.6 (2016): 587-609.

Padmajan Sasikala, Suchithra, Philippe Poulin, and Cyril Aymonier. “Prospects of supercritical fluids in realizing graphene‐based functional materials.” Advanced Materials 28.14 (2016): 2663-2691.

Ma Wenxiao. “Immobilization of natural macromolecules onto the surface of synthetic fabrics impregnated with cross-linking agents using supercritical carbon dioxide.” (2010).

Arakawa, Hironori, et al. “Catalysis research of relevance to carbon management: progress, challenges, and opportunities.” Chemical reviews 101.4 (2001): 953-996.