Research examining the effects of temperature and humidity on waterproof breathable fabrics’ vapor permeability is presented. Tests on various fabric types show atmospheric conditions substantially impact vapor permeability, with distinct behavioral differences among fabrics. This study identifies primary variables governing vapor permeability and develops predictive regression equations. The results inform the understanding of fabric capabilities in practical applications.

Physical activity generates insensible perspiration, which can lead to discomfort and performance reduction if not managed effectively. Clothing plays a crucial role in regulating body temperature, and waterproof breathable fabrics have emerged as a vital component in maintaining thermal comfort. These fabrics must balance water resistance with moisture vapor transmission to prevent heat buildup and potential health risks like hypothermia or hyperthermia.

The human body produces significant heat energy during strenuous activities, requiring efficient moisture management to maintain physiological acceptability. For instance, during intense exercise, the body can generate over 1 kW of heat, necessitating perspiration rates exceeding 1000 cm³ per hour. Fabrics with high water vapor permeability are essential to ensure comfort and performance.

Recent advancements in fabric technology have led to the development of various waterproof breathable materials, including densely woven fabrics, microporous membranes (e.g., Gore-Tex), non-poromeric hydrophilic membranes, and breathable coatings based on polyurethane. These innovations have expanded the applications of breathable fabrics beyond traditional sports and outdoor wear to everyday fashion.

Despite the growing market demand and technological advancements, there is a need to understand how different atmospheric conditions affect the water vapor permeability of waterproof breathable fabrics. This study investigates the performance characteristics of various fabric types under diverse temperature and humidity conditions, providing valuable insights for optimizing fabric design, selection, and use.

This introduction maintains the core information while adapting to the tone and focus of the title, emphasizing the importance of waterproof breathable fabrics during physical activity and setting the stage for the investigation into their performance characteristics.

The increasing popularity of waterproof breathable fabrics has led to a wide range of applications, from high-performance sportswear to everyday fashion. However, the effectiveness of these fabrics in managing moisture and maintaining thermal comfort is highly dependent on environmental conditions. Temperature, humidity, and wind speed can significantly impact the water vapor permeability of these fabrics, affecting their ability to regulate body temperature.

Existing standards for measuring water vapor permeability, such as vapor cup methods and heated wet plate tests, typically evaluate fabrics under controlled laboratory conditions. However, these conditions often fail to replicate the diverse atmospheric conditions encountered in real-world scenarios. Therefore, it is essential to investigate the performance of waterproof breathable fabrics under various temperature and humidity conditions to better understand their capabilities and limitations.

This study aims to address this knowledge gap by examining the water vapor permeability characteristics of different types of waterproof breathable fabrics under a range of atmospheric conditions. The findings will provide valuable insights for fabric manufacturers, garment designers, and end-users seeking to optimize the performance, comfort, and safety of waterproof breathable clothing.

| Fabric Type | Mass per Unit Area (g/m2) | Thickness (mm) |

| Densely woven cotton | 180 | 0.3 |

| Woven polyamide hydrophilic PU coating | 150 | 0.34 |

| 2-layer woven polyamide hydrophilic | 140 | 0.3 |

| 3-layer knitted polyamide microporous | 135 | 0.4 |

| Woven polyester microfilament polyester membrane | 40 | 0.2 |

For this study, five distinct types of waterproof, breathable fabrics were selected. Each represented a different category of fabric construction commonly used in the market for performance garments. The selection aimed to encompass a broad range of fabric technologies to provide a comprehensive evaluation of their water vapor permeability (WVP) under varying atmospheric conditions. The fabrics selected were:

Densely Woven Cotton: Traditionally, densely woven cotton fabrics were among the first scientifically engineered to be waterproof and breathable. When exposed to water, cotton fibers swell, reducing pore size and making the fabric resistant to water penetration. This makes it highly suitable for military applications such as those in extreme weather conditions (e.g., Ventile fabric developed for aircrew survival in cold waters). The densely woven cotton fabric in this study served as a benchmark due to its longstanding use in waterproof applications.

Woven Polyamide with Hydrophilic Polyurethane (PU) Coating: This fabric type features a synthetic polyamide base, coated with a hydrophilic polyurethane layer. The hydrophilic coating allows water vapor to diffuse through it by chemical absorption and diffusion, making it an efficient moisture-wicking layer while also preventing water from penetrating the fabric. Polyurethane coatings are commonly used in outdoor gear due to their durability and resistance to environmental wear.

Two-layer Woven Polyamide with a Hydrophilic Polyester Membrane: This laminated fabric construction consists of two layers: an outer woven polyamide fabric bonded to an inner hydrophilic polyester membrane. The membrane allows moisture to escape in vapor form, while its tightly structured lamination prevents water ingress. This type of fabric is commonly found in high-performance sportswear and outdoor gear.

Three-layer Knitted Polyamide with Microporous Polytetrafluoroethylene (PTFE) Membrane: This fabric is laminated with a microporous PTFE membrane (commonly known by its commercial name, Gore-Tex), a technology that revolutionized waterproof, breathable fabrics. The membrane contains billions of microscopic pores, large enough to allow water vapor molecules to pass through but small enough to block water droplets. This fabric is widely used in extreme weather protective clothing due to its high performance in both vapor permeability and waterproofing.

Woven Polyester with Micro-filament Structure: This fabric type features synthetic polyester filaments woven into a micro-filament structure. The micro-filaments provide a high surface area for water vapor to pass through, while the dense weave adds to the fabric’s water-resistant properties. This structure aims to balance flexibility, softness, and breathability, making it suitable for both fashion and functional outerwear.

To measure the water vapor permeability of the selected fabrics, a standard cup test method was employed, modified from British Standard 7209:1990, Appendix B. The method evaluates the WVP of fabrics by determining the mass of water vapor passing through a fabric over a given period.

The testing apparatus consisted of plastic cups filled with water, sealed with fabric specimens, and placed in an environmental chamber. The cups were designed to simulate conditions inside clothing during physical activity, where water vapor would rise from perspiration and attempt to pass through the fabric. A silicone sealant was used to ensure that vapor could only escape through the fabric and not through any gaps along the sides of the cup.

The environmental chamber was equipped to control temperature and relative humidity with precision. A water bath, maintained at 37°C, represented the internal temperature of the human body during moderate physical exertion. This was essential to replicate real-world conditions where clothing traps body heat, and water vapor needs to escape. The water bath was insulated with expanded polystyrene to minimize heat loss and keep the temperature constant throughout the tests.

The chamber was equipped with a fan to ensure that vapor did not accumulate over the fabric surface during testing. Without this, a microclimate with a higher relative humidity than the surrounding environment could form, influencing the results. By removing this vapor buildup, the fan helped maintain uniform atmospheric conditions and ensured that the measured WVP was due to the fabric’s inherent properties and not affected by external vapor buildup.

Each fabric sample was cut into circular sections large enough to cover the top of the cup. The cups were filled with water to a height of 10 mm from the rim, leaving a small air gap between the water surface and the fabric. The fabric samples were placed over the cup openings, sealed with silicone, and held in place by a cover ring to prevent any vapor leakage.

The cups were then placed inside the environmental chamber, where they were subjected to various combinations of temperature (ranging from 15°C to 45°C) and relative humidity (ranging from 40% to 90%). These environmental conditions were chosen to represent a wide range of weather scenarios that the fabrics might be exposed to in real-world applications, from cold and dry conditions to hot and humid environments.

Each fabric was tested at every temperature and humidity combination for five hours, after which the cups were removed from the chamber and weighed. The water vapor permeability (WVP) was calculated based on the mass of water lost from the cup during the test. The WVP values were expressed in gmday, which indicates the grams of water vapor passing through a square meter of fabric in a 24-hour period.

To quantify the water vapor permeability, the weight of the cups was recorded both before and after the testing period. The difference in weight represented the amount of water vapor that had passed through the fabric during the test. This difference was divided by the fabric area and time to calculate the WVP for each fabric under each condition.

The data were further analyzed to determine the relationship between WVP and vapor pressure difference. Vapor pressure difference is a key variable in understanding moisture transfer through fabrics, as it represents the driving force that pushes water vapor from the inside of the garment to the outside environment. The vapor pressure difference was calculated based on the water temperature in the cup (simulating body temperature) and the external atmospheric conditions (temperature and humidity).

Regression analysis was used to develop equations that describe the relationship between WVP and vapor pressure difference for each fabric. These equations were used to predict fabric performance under other atmospheric conditions not directly tested in the experiment. The equations took the form of third-degree polynomials, as the relationship between WVP and vapor pressure difference was found to be non-linear.

The cup test method was chosen for its simplicity and widespread acceptance in the textile industry for measuring water vapor permeability. While other methods, such as the sweating guarded hotplate or dynamic moisture permeability tests, exist, the cup method allows for precise control over environmental conditions and direct measurement of water vapor loss. Furthermore, it provides a reproducible and quantifiable measure of fabric performance under controlled conditions, which is critical for developing comparative data across multiple fabric types.

The choice of temperature and humidity ranges reflects the varying conditions in which waterproof breathable fabrics are typically used. Cold, dry conditions (15°C and 40% humidity) simulate high-altitude or winter environments, while hot, humid conditions (45°C and 90% humidity) replicate tropical or desert climates. By testing across this spectrum, the study captures a comprehensive view of fabric performance.

Moreover, the simulated body temperature (37°C) ensures that the results are relevant to real-world scenarios, where moisture from perspiration drives the need for breathable fabrics. By using a controlled setup with a fan to prevent microclimate effects, the experiment focuses on the intrinsic properties of the fabrics rather than external factors.

The evaluation of water vapor permeability (WVP) for the five fabric types revealed significant variations based on fabric construction and environmental parameters such as temperature and relative humidity. The results are discussed in detail below.

The five fabrics tested exhibited a clear hierarchy in terms of vapor permeability:

Woven Polyester Micro-filament Fabric: This fabric demonstrated the highest WVP across all conditions, reaching up to 7401 g\(\cdot\)m\(^{-2}\cdot\)day\(^{-1}\) at 15\(^\circ\)C and 40% relative humidity. The high performance is attributed to its micro-filament structure, providing a large surface area for moisture transfer while maintaining an open weave.

Densely Woven Cotton: Densely woven cotton also showed strong WVP, with values reaching 7039 g\(\cdot\)m\(^{-2}\cdot\)day\(^{-1}\). However, it displayed a decrease in permeability at higher temperatures and humidity levels, suggesting less effectiveness under more strenuous conditions.

Microporous PTFE Membrane: The microporous PTFE membrane (e.g., Gore-Tex) showed intermediate levels of WVP, reaching 6240 g\(\cdot\)m\(^{-2}\cdot\)day\(^{-1}\) at 15\(^\circ\)C. Its performance dropped significantly at higher temperatures and humidity levels.

Hydrophilic Polyester Membrane: This fabric showed lower permeability, with a maximum WVP of 4898 g\(\cdot\)m\(^{-2}\cdot\)day\(^{-1}\), mainly due to its reliance on diffusion rather than physical pores for vapor transmission.

Hydrophilic Polyurethane Coating: The lowest WVP was observed in the polyurethane-coated fabric, starting at 4463 g\(\cdot\)m\(^{-2}\cdot\)day\(^{-1}\), attributed to the thick coating that impedes moisture diffusion.

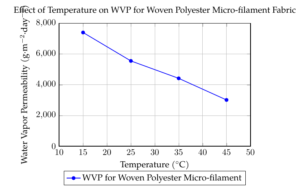

Temperature had a significant impact on WVP. As shown in Figure 1, increasing the temperature from 15\(^\circ\)C to 45\(^\circ\)C led to a decrease in WVP for all fabrics. The WVP of the woven polyester micro-filament fabric decreased from 7401 g\(\cdot\)m\(^{-2}\cdot\)day\(^{-1}\) at 15\(^\circ\)C to 3011 g\(\cdot\)m\(^{-2}\cdot\)day\(^{-1}\) at 45\(^\circ\)C. The microporous PTFE membrane similarly experienced a drop, from 6240 g\(\cdot\)m\(^{-2}\cdot\)day\(^{-1}\) to 2358 g\(\cdot\)m\(^{-2}\cdot\)day\(^{-1}\).

Hydrophilic fabrics showed even sharper declines. The hydrophilic membrane dropped from 4898 g\(\cdot\)m\(^{-2}\cdot\)day\(^{-1}\) to 1560 g\(\cdot\)m\(^{-2}\cdot\)day\(^{-1}\), while the polyurethane-coated fabric dropped to 1487 g\(\cdot\)m\(^{-2}\cdot\)day\(^{-1}\) at 45\(^\circ\)C.

Relative humidity also influenced WVP significantly. As the external humidity increased from 40% to 90%, the WVP of all fabrics decreased. At 90% relative humidity, several fabrics, including the microporous PTFE and hydrophilic membranes, exhibited negative WVP values at higher temperatures (45\(^\circ\)C), indicating moisture transfer from the outside to the inside of the fabric.

The woven polyester micro-filament fabric maintained positive WVP values at high humidity, but still experienced a significant drop in performance, from 7401 g\(\cdot\)m\(^{-2}\cdot\)day\(^{-1}\) to -871 g\(\cdot\)m\(^{-2}\cdot\)day\(^{-1}\) at 45\(^\circ\)C and 90% relative humidity.

The results demonstrate that fabric construction significantly affects WVP. Fabrics with more open structures, such as the woven polyester micro-filament and densely woven cotton, had the highest permeability values. These fabrics are ideal for high-performance applications where breathability is critical, such as outdoor sports or military environments.

In contrast, fabrics with hydrophilic coatings or membranes, which rely on diffusion rather than pores, exhibited lower permeability. These fabrics may be more suitable for applications where durability and waterproofing are prioritized over breathability, such as everyday outerwear.

As expected, increasing temperature and humidity both negatively impacted WVP. The decrease in WVP with rising temperature is explained by the reduction in the vapor pressure gradient between the inside and outside of the fabric. At higher external temperatures, the driving force for moisture transfer diminishes, reducing the effectiveness of even the most breathable fabrics.

Similarly, higher humidity levels reduce the ability of fabrics to transmit moisture. In extreme conditions (90% humidity and 45\(^\circ\)C), fabrics such as the hydrophilic membrane and microporous PTFE membrane exhibited negative WVP values, suggesting reverse moisture transfer due to external saturation.

The practical implications of these findings are significant for both manufacturers and consumers. High-performing fabrics like woven micro-filaments and microporous PTFE membranes are well-suited for dry, cool environments, but may struggle in hot, humid conditions. For such climates, additional garment ventilation may be necessary to maintain wearer comfort.

In less demanding environments, fabrics with hydrophilic coatings can provide sufficient breathability for moderate activities. However, individuals engaged in high-intensity activities or exposed to extreme conditions should prioritize fabrics with higher WVP values to ensure comfort and performance.

Although the study covers a broad range of fabrics and environmental conditions, it is important to recognize that the relationship between WVP and atmospheric conditions is complex. Future studies could focus on dynamic testing environments that simulate more realistic conditions, such as fluctuating temperatures or periods of physical exertion.

Furthermore, the use of advanced testing methods, such as the sweating guarded hotplate, could provide more detailed insights into fabric performance, particularly under conditions of active perspiration.

Tehrani-Bagha, Ali Reza. “Waterproof breathable layers–A review.” Advances in colloid and interface science 268 (2019): 114-135.

Razzaque, Abdur, et al. “Investigation on hydrostatic resistance and thermal performance of layered waterproof breathable fabrics.” Fibers and Polymers 18 (2017): 1924-1930.

Holmes, David A. “Waterproof breathable fabrics.” Handbook of technical textiles 12 (2000): 282.

Kim, Hyun-Ah. “Water repellency/proof/vapor permeability characteristics of coated and laminated breathable fabrics for outdoor clothing.” Coatings 12.1 (2021): 12.

Mukhopadhyay, Arunangshu, and Vinay Kumar Midha. “A review on designing the waterproof breathable fabrics part I: fundamental principles and designing aspects of breathable fabrics.” Journal of industrial textiles 37.3 (2008): 225-262.

Armağan, O. Gazi, and H. Karakaş. “A study of performance and comfort properties of waterproof breathable laminated knitted fabrics.” Tekstil: Journal of Textile & Clothing Technology 57.12 (2008).

Oh, Eunkyung, Eunae Kim, and Youngmi Park. “Evaluation of the moisture transfer property of waterproof breathable fabric under low-temperature conditions depending on the pore size and distribution.” Clothing and Textiles Research Journal 36.4 (2018): 310-323.

Su, Y., et al. “Application of waterproof breathable fabric in thermal protective clothing exposed to hot water and steam.” IOP Conference Series: Materials Science and Engineering. Vol. 254. No. 4. IOP Publishing, 2017.

Sarkar, K., et al. “Macro-structured carbon clusters for developing waterproof, breathable conductive cotton fabric.” Carbon 116 (2017): 1-14.

Ryu, Yeon Sung, Kyung Wha Oh, and Seong Hun Kim. “Furan-based self-healing breathable elastomer coating on polylactide fabric.” Textile Research Journal 89.5 (2019): 814-824.

Jassal, Manjeet, et al. “Waterproof breathable polymeric coatings based on polyurethanes.” Journal of Industrial Textiles 33.4 (2004): 269-280.

Gu, Xianyuan, et al. “Polydimethylsiloxane‐modified polyurethane–poly (\(\varepsilon\)‐caprolactone) nanofibrous membranes for waterproof, breathable applications.” Journal of Applied Polymer Science 135.23 (2018): 46360.

Yu, Yunge, et al. “Waterproof and breathable polyacrylonitrile/(polyurethane/fluorinated-silica) composite nanofiber membrane via side-by-side electrospinning.” Journal of Materials Research 35.9 (2020): 1173-1181.