Polypropylene insulation materials for power cables were prepared using a mixer blending process, and the high and low-temperature performance, electrical performance, and aging performance of different formulation materials were studied. By comparing and analyzing the properties of copolymerized and uniformly clustered polypropylene resins, it was found that the basic physical properties of copolymerized polypropylene resins and their compatibility with other modified resins were better than those of uniformly clustered polypropylene resins. Using copolymer polypropylene as the matrix resin and adding different types of modified resins for comparative analysis, it was found that PER-modified resins can improve the low-temperature performance of polypropylene resin while maintaining the electrical properties of insulation materials. Through DSC oxidation induction experiments, it was found that adding antioxidants composed of 300 # and 168 # to the formula of block copolymer polypropylene and PER-modified resin as substrates can improve the aging performance of the material while ensuring electrical and low-temperature performance.

Polypropylene is a thermoplastic resin obtained by polymerizing propylene as a monomer. It has a regular structure, high crystallinity, and good corrosion and heat resistance. Polypropylene can be divided into isotactic polypropylene (iPP), syndiotactic polypropylene (sPP), and atactic polypropylene (aPP) according to the arrangement of their methyl groups. Polypropylene has a melting point of over 150 \(^\circ C\), which is about 40%-50% higher than polyethylene. Its long-term working temperature can reach 90 \(^\circ C\).

Good heat resistance is significant for improving the working temperature and voltage of cables. Polypropylene is a non-polar material with high breakdown strength (mostly around 300 kV/mm), high volume resistivity (mostly around \(10^{16} \, \Omega \cdot m\)), and minimal change with temperature. It can increase the operating voltage of cables, enhance the transmission capacity of lines, and reduce transmission losses with the same insulation layer thickness. Polypropylene has less space charge accumulation and a higher threshold electric field for charge injection. Polypropylene hardly absorbs water, so its insulation performance is less affected by environmental humidity.

Research has shown that isotactic polypropylene can meet the requirements of insulation material for DC cables in terms of voltage resistance and conductivity characteristics [1]. Therefore, polypropylene has attracted widespread attention due to its excellent electrical and heat resistance properties, as well as its suitability for environmentally friendly and recyclable cable insulation materials. However, polypropylene also has drawbacks, such as high low-temperature brittleness, poor heat aging resistance, unstable electrical performance across temperature extremes, and low thermal conductivity, which limit its application in power cable insulation [2]. To use polypropylene-based environmentally friendly insulation materials in high-voltage cable insulation, these issues must be addressed.

At present, foreign petrochemical giants can produce sPP products with excellent overall performance using metallocene catalysts [3]. Therefore, research on polypropylene-based environmentally friendly insulation materials primarily focuses on sPP. As early as 2002, scholars investigated the feasibility of applying sPP to the main insulation material of power cables. Aakre et al. [4] were the first to use sPP as the main insulation, blending it with PE and antioxidants for 0.6 kV and 22 kV cables. They found that the AC breakdown strength and dielectric loss of the cable line at different temperatures met practical application requirements. The study also found that the electrical, thermal, and mechanical properties of sPP are superior to those of iPP, aPP, and PE. The 22 kV cable prepared by blending sPP and elastomer exhibited excellent electrical performance and recyclability. Prysmian, an Italian company, publicly released a high-performance thermoplastic elastomer insulation material developed from polypropylene materials in 2010.

Research suggests that P-Laser cables, developed based on HPTE (High Performance Thermoplastic Elastomer) materials, have better electrical performance than traditional XLPE cables and better mechanical properties than conventional polypropylene materials [5]. The company announced the latest prototype sample of a full-size P-Laser 320 kV high-voltage DC cable in 2015. Currently, Prysmian is moving towards using polypropylene-based materials as the primary insulation material for high-voltage DC cables [6].

In China, as petrochemical companies lack the capacity to synthesize and produce sPP products, scholars primarily obtain polypropylene-based cable insulation materials with excellent performance by modifying iPP. The research conducted by He Jinliang’s group at Tsinghua University and Jiang Pingkai’s group at Shanghai Jiao Tong University is particularly comprehensive [7]. By studying the toughening and modification of iPP with POE and ethylene propylene adhesive, they achieved good mechanical properties, and effectively suppressed space charge accumulation in iPP by adding nanoparticles such as MgO or ZnO, yielding positive results [8]. Recently, they also prepared prototype samples of 10 kV power cables using iPP-based insulation materials for further performance evaluation [9]. Additionally, Professor Du Boxue’s group at Tianjin University has conducted similar research [10].

Building on the above research, this article uses polypropylene as the matrix resin and adds various types and quantities of modified resins. High-temperature and low-temperature properties of the modified materials are studied through hot deformation and low-temperature embrittlement experiments. Using a high-resistance meter, the room-temperature and high-temperature electrical properties of the blend material are analyzed to select the optimal combination of polypropylene and modified resin. Based on this combination, different types of antioxidants are added, and their aging performance is analyzed through DSC oxidation induction and air thermal aging experiments. Finally, the formulations and materials that meet the requirements are selected.

Homopolymer polypropylene (T30S): Melt index 2-4g/10min, tensile strength 30MPa, Vicat softening point 150 \(^\circ C\), melting temperature 161-163 \(^\circ C\), Sinopec; Block copolymer polypropylene (K8303): Melt index 1-3g/10min, tensile strength 22MPa, Vicat softening point 145 \(^\circ C\), melting temperature 161-163 \(^\circ C\), Zhenhai Refining and Chemical; Random copolymer polypropylene (M250E): Melt index 2-4g/min, tensile strength 22MPa, Vicat softening point 110 \(^\circ C\), melting temperature 135-142 \(^\circ C\), Sinopec; POE 8480 (ethylene octene copolymer): Melt index 1-3g/10min, tensile strength 28MPa, Dow, USA; PER 6202 (propylene ethylene octene copolymer): melt index 8-10g/10min, tensile strength 5.8MPa, ExxonMobil; EMA 1125AC (ethylene methyl acrylate copolymer): melt index 1-2g/10min, tensile strength 14MPa, Dow DuPont; Antioxidant 1010: BASF; Antioxidant 168: BASF; Antioxidant 300: Beijing Yiyi Chemical.

Heat aging experimental chamber: XG-CN, Nantong Hongda Experimental Instrument; Electronic balance: AE523J, Shunyu Hengping instrument; ZC36 high resistance meter: ZC-36, Shanghai Jingke Sixth Meter; Hot extension test chamber: RY130, Changshu Environmental Testing Equipment Co., Ltd; Thermal deformation testing device: YL-UL, Changshu Environmental Testing Equipment Co., Ltd; Differential scanning calorimeter: Q2000, American TA instrument; Torque rheometer: RM-200A, Harbin Hapu Electric; Plastic ultra-low temperature brittleness tester: BC-2, Shanghai Pengpu Refrigerator.

The process flow for sample preparation is shown in Figure 1.

Weigh the sample according to the proportion specified in the formula, ensuring that the weight is between 160g and 180g.

Pour the weighed granular materials into the mixer, with an initial set temperature of 170 \(^\circ C\) and a speed of 30 RPM. After mixing the materials for 2 minutes, add powdered materials and adjust the speed to 60 RPM. After mixing for 10 minutes, remove the materials.

Accurately weigh the corresponding mass of materials according to the different volume of the mold, and then preheat for 10 minutes without pressure in a flat plate fluidized bed at a temperature of 200 \(^\circ C\), then heat and pressurize for 5 minutes, and then pressurize and cool to room temperature for demolding. The pressure is set at 15 MPa, and the demolded test piece should be flat, smooth, uniform in thickness, and free of bubbles.

The tensile performance and thermal aging test shall be carried out in accordance with the provisions of GB/T1040-2008 “Determination of tensile properties of plastics – Part 3- Test conditions for films and sheets”. The sample shall be type 5 with a thickness of 1.0mm.

The test is carried out in accordance with the provisions of GB/T5470-2008 “Determination of embrittlement temperature by impact method”, and the sample thickness is set to 2.0mm. Hot deformation sample preparation: The test is carried out in accordance with the provisions of 6.4 in GB/T8815-2008, and the sample thickness is set to 1.25mm. Electrical performance sample preparation: The test shall be conducted in accordance with the provisions of GB/T1409-2008, and the sample thickness shall be set at 1.0mm.

According to the GB/T 5470-2008 standard method, the initial test temperature is -30 \(^\circ C\). If the sample passes the -30 \(^\circ C\) low temperature impact, the temperature is lowered by 5 degrees, and so on, until the 30 tested samples break more than 15. The results of low-temperature embrittlement can reflect the toughening effect of modified materials on polypropylene, and can also provide feedback on the blending situation between modified materials and polypropylene materials.

Conduct the test according to the method in Chapter 6.4 of GB/T 8815-2008, with a test temperature of 130 \(^\circ C\) and a pressure of 1Kg; Using this method to replace the testing method of cross-linked polyethylene thermal elongation can better reflect the deformation of modified polypropylene materials under load conditions.

According to the standard method of GB/T 1409-2008, the electrical performance of modified samples is tested at temperatures of 90 \(^\circ C\) and 23 \(^\circ C\). Before testing, the samples need to be kept at the testing temperature for 30 minutes. The high temperature electrical performance can better reflect the stability of polypropylene materials under heating conditions, that is, electric energy transmission conditions.

Before testing the tensile strength and elongation at break, the sample should be subjected to constant temperature and humidity conditions Place it in (23 \(^\circ C\), 55% humidity) for 4 hours, select a stretching rate of 100mm/min during testing, test each sample 7 times, remove the highest and lowest values, and take the average of the remaining 5 samples as the test result. The aging condition is 135 \(^\circ C\) × 168 hours. After aging, the sample should be placed in a constant temperature and humidity (23 \(^\circ C\), 55% humidity) for 16 hours before testing. The stretching rate is selected as 100mm/min, and each sample is tested 7 times. The highest and lowest values are removed, and the average value of the remaining 5 samples is taken as the test data. And calculate according to the aging calculation method in GB/T 1410-2008.

The test material should be placed in a constant temperature and humidity (23 \(^\circ C\), 55% humidity) for 4 hours, then placed in a DSC device and heated under pure oxygen conditions. The initial temperature is 80 \(^\circ C\), and the heating rate is 10 \(^\circ C\)/minute. The heating should stop at 400 \(^\circ C\).

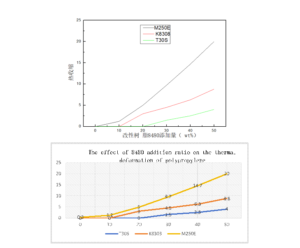

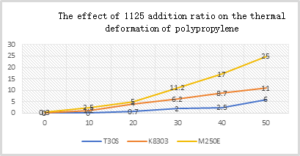

Crosslinked polyethylene insulation materials usually use thermal elongation to determine the deformation ability of the material under load conditions, while modified polypropylene materials belong to thermoplastic resins. Using thermal deformation testing methods can better reflect the characteristics of modified polypropylene at high temperatures. The specific results are shown in Figures 2-4.

In the above three charts, the total amount of resin is 100 parts. By adding 10 to 50 parts of modified resin proportionally, it can be seen that the thermal deformation data of the three polypropylene materials increases with the increase in modified resin addition. This is directly related to the fact that the thermal deformation temperature of the three modified resins is lower than that of polypropylene resin. Due to the low melting point of M250E, its thermal deformation data and curve trend are also larger than the other two high-melting-point resins.

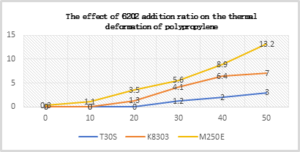

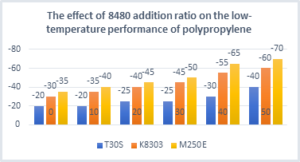

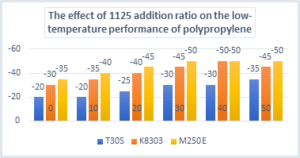

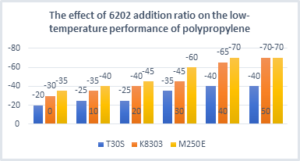

For cross-linked polyethylene materials, the low-temperature embrittlement temperature can reach -76 \(^\circ C\). Polypropylene materials themselves have the disadvantage of poor low-temperature toughness, so it is crucial to study the effect of modified resins on the low-temperature performance of polypropylene materials, as shown in Figures 5-7.

| 1# | 2# | 3# | 4# | 5# | 6# | 7# | 8# | 9# | |

| K8303 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| 6202 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| 1010 | 0.6 | 0.3 | 0.3 | 0.2 | 0.3 | 0.2 | |||

| 168 | 0.6 | 0.3 | 0.3 | 0.1 | 0.1 | 0.3 | |||

| 300 | 0.6 | 0.3 | 0.3 | 0.3 | 0.2 | 0.1 | |||

| Change rate after aging | |||||||||

| Intensity Change Rate | -15% | -17.7% | -13.1% | -7.1% | 5.2% | -13.3% | -2.3% | -7.8% | -9.1% |

| Elongation Change Rate | -25.7% | -27.3% | -17.2% | -11.2% | -7.6% | -19.8% | -8.5% | -17.6% | -11.7% |

From the above three charts, it can be seen that as the proportion of modified resin added increases, the low-temperature embrittlement temperature of polypropylene materials also decreases accordingly, indicating that modified resin can have a toughening effect on polypropylene materials. After being added to 30 parts, modified resin 1125 did not significantly improve the low-temperature effect of polypropylene. This is because 1125 itself is a polar resin with poor compatibility with polypropylene. After reaching a certain addition ratio, phase separation will occur at the micro level. The other two modified resins are non-polar resins that have good compatibility with polypropylene. Adding them to a certain amount can achieve better low-temperature resistance.

Considering the improvement effect of modified resin on the high-temperature hot deformation and low-temperature embrittlement of polypropylene, due to its strong rigidity, the low-temperature modification effect of homopolymer T30S is still not significant when the modified resin is added to more than 40 parts, while the modification effect of the other two resins is more obvious. When the modified resin is added to more than 30 parts, the thermal deformation data of M250E resin with random copolymerization changes significantly, while the deformation of the other two resins is relatively small.

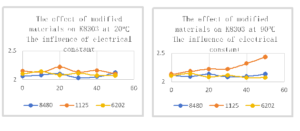

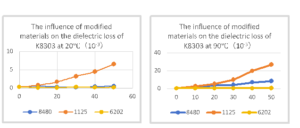

Polypropylene materials have excellent electrical properties due to the symmetry of their molecular structure. In order to study the electrical properties of modified polypropylene materials at room temperature and normal working conditions, this paper analyzes the dielectric constant and dielectric loss factor of modified polypropylene materials at temperatures of 20 \(^\circ C\) and 90 \(^\circ C\), as shown in Figures 8 and 9.

From Figure 8, it can be seen that at 20 \(^\circ C\), the modified resin has little effect on the relative dielectric constant of K8303. At 90 \(^\circ C\), the relative dielectric constant of resins modified with 8480 and 6202 remains stable. The influence of 1125 on the dielectric constant of K8303 increases with the increase of the fraction. This may be due to the low molecular chain activity of polypropylene and modified resins at room temperature, where polypropylene, as the main resin, plays a dominant role in the material’s ability to store charges. At high temperatures, the molecular chain activity of polypropylene increases, and the intermolecular gaps become larger, providing space for polar material 1125 molecules, increasing the material’s ability to store charges, leading to an increase in the relative dielectric constant.

From Figure 9, it can be seen that at 20 \(^\circ C\), with the increase of non-polar modified resin, the change in dielectric loss is not significant, but the increase of 1125 parts of polar resin has a significant impact on dielectric loss. At 90 \(^\circ C\), the dielectric loss of non-polar resin 8480 also increases with the increase of the fraction. This is because 8480 is an ethylene octene copolymer, which has a different molecular structure from propylene. Under high temperature conditions, the molecules present a phase separation state, resulting in increased loss. Meanwhile, 6202 is a ternary copolymer of ethylene, propylene, and octene. The modified resin containing propylene groups has good compatibility with K8303 and a high degree of intermolecular bonding under high temperature conditions.

Considering electrical performance, polypropylene K8303 and modified resin 6202 have the best performance at room temperature and working temperature. Combined with the low-temperature and hot deformation performance, K8303 and 6202 show the best comprehensive performance when blended in a 1:1 ratio.

This paper selects three commonly used antioxidants for analysis, as shown in Table 1.

Comparing formulas 1#, 2#, and 3# in Table 1, it was found that the three antioxidants used alone had poor anti-thermal oxidative aging effects on modified polypropylene. The anti-thermal oxidative aging effects of formulas 4# and 5# were significantly improved compared to formulas 6#, indicating that 300# antioxidants play a major role in the anti-thermal oxidative aging of modified polypropylene systems. When combined with a certain proportion of other antioxidants, it can better inhibit the separation and degradation of polypropylene branches. Among the formulas, antioxidant 300# has the best anti-thermal oxidative aging effect when the ratio reaches 0.3 parts.

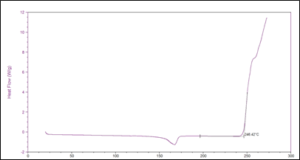

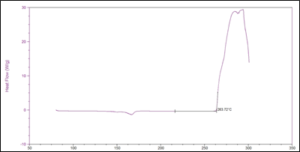

To further verify the anti-thermal oxidative aging effect of formulas 4#, 5#, and 7#, DSC was used for oxidation induction experiments, as shown in Figures 10-12.

From the above figures, it can be seen that the oxidation induction temperature of formula 5# is the highest.

This article further investigates the use of homopolymer polypropylene T30S, block copolymer polypropylene K8303, and random copolymer polypropylene M250E as matrix resins, and the addition of different types and fractions of modified resins to achieve the relevant properties of cross-linked polyethylene. Through hot deformation and low-temperature embrittlement experiments, it was found that the low-temperature and deformation resistance of the modified resin were improved when mixed with K8303; Through the analysis of the relative dielectric constant and dielectric loss factor of modified resin at room temperature and 90 \(^\circ C\) high temperature conditions, it was found that the electrical performance of ternary copolymerized 6202 resin and K8303 was the best when mixed in a 1:1 ratio; On the basis of this combination, different types of antioxidants were selected, and through DSC oxidation induction analysis, it was determined that adding 0.3 parts of 300 # and 0.3 # of 168 # antioxidants can achieve the best antioxidant effect. The research results have good reference value for environmentally friendly polypropylene insulation materials.