In this topic, the sub-industry data of 28 manufacturing industries in each province are selected as the data source, and the research variables are discussed and determined. Considering the spatial effect, the spatial weight matrix is added, while the spatial autocorrelation test is conducted by applying the formula for calculating the Moran index. After passing the test, a spatial econometric model is constructed with the purpose of producing technological innovation affecting the level of sustainable development. The regression coefficients of technological progress change (tech) and technological efficiency change (effch) are 1.718 and 1.644, respectively, which passed the significance test at 1% significance level In addition, in the analysis of the robustness results, the regression coefficients of technological progress change (tech), technological efficiency change (effch) and product innovation (lnSPI) are 1.704, 1.753, while the regression coefficient of invention patent application authorization and product innovation (lnSPI) is 0.105. It is obvious that the influence of technological progress change (tech) and technological efficiency change (effch) is more significant, and plays a key role in the green sustainable development of manufacturing industry.

As the world attaches increasing importance to environmental protection and sustainable development, the manufacturing industry is gradually realizing green transformation, which has also become an important means of promoting industrial transformation and upgrading and realizing sustainable development. By promoting green manufacturing concepts and technologies, and actively promoting green manufacturing technology innovation and application, China’s manufacturing industry has moved towards the green international development road. On the one hand, as countries around the world are increasingly enhancing the endogenous momentum of green development, and are committed to upgrading the carbon neutral capacity after the carbon emission peaks, the green and low-carbon competitive advantages of the manufacturing industry in the global industrial chain supply chain are gradually coming to the fore [1,2]. Green development has become the universal form of new industrialization, leading the global manufacturing industry to move forward in the direction of more environmental protection and high efficiency [3]. On the other hand, in order to promote the green development of the manufacturing industry, traditional industries are undergoing a profound transformation, which includes the optimization and adjustment of the product structure, energy use structure, raw material structure, as well as the reengineering of the process flow [4,5]. These changes aim to improve the energy efficiency and resource utilization of the manufacturing industry, reduce environmental pollution, and thus promote the transformation of the manufacturing industry to a green, low-carbon, and circular development mode [6,7]. By applying advanced technologies such as big data, cloud computing, and artificial intelligence, the manufacturing industry can achieve more accurate resource utilization, more efficient energy management, and more environmentally friendly production processes [8,9]. These efforts aim to enhance the position and competitiveness of the manufacturing industry in the global division of labor, and at the same time build a clean, efficient, and low-carbon industrial energy consumption structure, which not only helps to enhance the competitiveness of the manufacturing industry, but also is of great significance in addressing global climate change and realizing green and sustainable development.

As resource and environmental constraints become tighter and tighter, how to promote the green transformation of enterprises and achieve the goal of sustainable development under the new conditions has become a realistic issue worthy of study. Literature [10] summarizes and classifies a series of obstacles for SMEs before achieving sustainability plans, and the results show that resource shortage, high cost and lack of professional knowledge are common sustainability barriers for SMEs. Literature [11] explored the impact of social responsibility on corporate environmental sustainability and, after analyzing a sample of manufacturing industry data, found that all dimensions of corporate social responsibility positively impacted on driving their environmental sustainability and had a greater impact on businesses than on consumers. Literature [12] assessed the role of environmental management systems (EMS) in improving corporate sustainability and showed that firms adopting EMS significantly improved their performance and promoted environmental protection and social equity, and that the adoption of EMS can be an effective tool for organizations to address economic, social, and environmental issues. Literature [13] discussed the role of green human resource management (HRM) in contributing to the environmental performance of firms, HRM develops the enablers of green organizational culture through the implementation of environmentally related practices, which in turn improves the environmental performance of firms. Literature [14] found that stakeholder pressures, such as consumer and regulatory pressures, influence firms’ green innovation through different organizational learning styles, including firms’ product and process innovation capabilities, which in turn help firms to achieve sustainable development goals. Literature [15] analyzed the impact of green intellectual capital on sustainable performance, which as an intangible resource enhances the competitive advantage of green manufacturing firms and researchers, and positively affects economic, environmental and social performance.

The use of production technology innovation to enhance the environmental competitiveness of enterprises is not only reflected in quality improvement and productivity advantages, but also in environmental friendliness and efficient and reusable utilization of resource products. Literature [16] observes the progress of corporate sustainability technologies from a holistic perspective, and through case assessment finds that eco-innovations in business integration, green marketing, and hybrid model construction and optimization need to be enhanced by new technologies and directions. Literature [17] explores the impact of lean manufacturing on business operations and economic performance from three perspectives: economic growth, environmental protection, and social responsibility, and describes the growing trend of future growth in the increasing development of lean manufacturing. Literature [18] shows that advanced manufacturing capabilities in the context of Industry 4.0 technologies promote sustainable development outcomes for enterprises, and Industry 4.0 delivery systems effectively overcome various challenges faced by enterprises in circular economy models by regulating the degree of implementation paths and advanced manufacturing capabilities to help resources remain in the system to complete the cycle. Literature [19] constructed an analytical framework for integrating Industry 4.0, sustainable manufacturing and circular economy in the context of supply chain management, emphasizing the need for firms to focus on sustainable manufacturing capabilities and to clear barriers using Industry 4.0 technologies in order to develop their circular economy capabilities. Literature [20] examined the combined impact of Industry 4.0 technologies on lean manufacturing practices and sustainable organizational performance, and investigated that Industry 4.0 technologies not only directly affect sustainable organizational performance, but also indirectly affect sustainable organizational performance by enabling lean manufacturing practices. Literature [21] suggests that Industry 4.0 has the potential to develop environmental sustainability in manufacturing and that production synergies between the two will reshape current production and consumption patterns. Literature [22] establishes a conceptual framework describing the relationship between enterprises’ green technology innovation capability and enterprise competitiveness, and finds that enterprises’ competitiveness is significantly improved by adjusting different green technology innovation elements through product differentiation, and that different innovation components have different degrees of impact on enterprise competitiveness. Literature [23] clarified the significance of green technology (GTI) and industrial revolution 4.0 technology (IR4.0) in the joint efforts of the industry and the government to achieve a green balance and sustainable development, GTI facilitates green innovation of products and increases the use of natural resources, and IR4.0 helps ecological security through big data detection and analysis, which together promote the realization of sustainable development goals. Literature [24] provides a micro perspective level analysis of the nonlinear relationship between environmental regulation, technological innovation and enterprise value, and the experimental results show that the total effect between environmental regulation and enterprise value is in the form of a u-shape and enterprise technological innovation plays a part of the mediating effect in it.

This topic defines relevant concepts and selects 28 sub-industries of manufacturing industries in each province as samples from 2012 to 2021. Based on relevant references and experts’ suggestions, model variables are set and variable indicators and quantification methods are determined. In order to effectively measure the spatial variability, the spatial weight matrix is added to the variables, while the autocorrelation is tested by the global Moran index. After passing the spatial autocorrelation test, the construction of the spatial econometric model is formally started next. Sample data are introduced into the completed model to explore the role of production technology innovation in boosting the realization of green sustainable development goals in the manufacturing industry.

Production technology innovation should include the improvement of the original production conditions, new product development, commercialization and other links. This paper, based on the existing research results, defines the enterprise production technology innovation in the context of green production as follows: In order to realize sustainable economic development, the enterprise takes environmental protection as the starting point, and with the help of new scientific and technological achievements, brings the idea of environmental regulation into the change of the original production factors, modes, conditions, and processes, and establishes a new environmentally friendly production function, which includes the research and development of new products, acquisition of new raw materials, introduction of new processes, opening up of new markets, creation of new economic value, and establishment of a new organization. It includes a series of economic and technological activities such as the research and development of new products, the acquisition of new raw materials, the introduction of new processes, the opening up of new markets, the creation of new economic value, and the establishment of a new enterprise organization. Technological innovation in production is usually regarded as a commercial activity, the first commercial application of a new technology. Technological innovation in production depends on a combination of real demand and real technology, with demand determining the remuneration for innovation and technology determining the likelihood of success and cost.

The concept of manufacturing industry is the use of materials, energy, equipment, tools, capital, technology, information and manpower and other resources, according to market demand, through the production chain, manufactured into large-scale tools for people to use and utilize, industrial goods and consumer products for life of the industry . The outline document released in 2017 for the latest classification of manufacturing industry, the document will be classified into 28 specific industries in the manufacturing industry, and also in the paper The manufacturing industry classification standard selected in the subsequent empirical evidence.

The concept of sustainable development refers to “development that meets the needs of the present without jeopardizing the ability of future generations to meet their own needs”. Sustainable development is more of a sustainable mass production and resource conservation idea. With the development, the concept of sustainable development now moderates the antagonistic relationship between development and environmental protection, and advocates the establishment of an environmentally friendly society in which human beings and nature live together in a friendly manner. The manufacturing industry has been developing in a more responsible way: on the one hand, it is required to shoulder social and environmental responsibilities, such as the goal of “ensuring sustainable consumption and production patterns”, which requires the manufacturing industry to promote innovation in production methods with the goal of sustainable development. On the other hand, it is required that manufacturing development should support the achievement of social and environmental goals, such as the goal of “promoting inclusive and sustainable industrialization and fostering innovation”, which relies on the support and contribution of manufacturing to sustainable development.

The data of the research sample of this paper comes from the data of 28 manufacturing sub-industries in each province, and the examination period is according to 2012-2021. The raw data come from the 2012-2021 Statistical Yearbook of a Province and Industrial Economic Yearbook. Since the statistics on pollutant sub-industry data in the relevant yearbooks only officially started in 2012, this paper takes 2012 as the first period. At the same time, since the data on “three wastes” and their treatment by industry have been missing from the “Statistical Yearbook of a Province” since 2013, this paper sets the end of the data as 2021 for the sake of completeness and authenticity of the obtained data.

In order to measure the enterprise production technology innovation variables, this paper takes the total industrial output value as the output variable, the annual average number of all employees in the manufacturing industry and the capital stock of the sub-industry as the input variables, and deflates them by the industrial factory price index of the sub-industry with 2013 as the base period. The Malmquist productivity index is used to calculate the production technology progress rate of 28 industries in the manufacturing sector in Jiangsu Province, in which the Malmquist productivity index is measured by using the DEAP2.1 software.The Malmquist productivity index can be decomposed into the change in technological progress (tech) and the change in technological efficiency (effch), in which the change in technological efficiency is superior can be further decomposed into pure technical efficiency change (pech) and scale efficiency change (sech). Namely: \[M_{i} \left(y^{s} ,x^{s} ,y^{t} ,x^{t} \right)=\frac{D_{v}^{t} \left(y^{t} ,x^{t} \right)}{D_{v}^{s} \left(y^{s} ,x^{s} \right)} \bullet \left[\frac{D_{v}^{s} \left(y^{s} ,x^{s} \right)}{D_{v}^{t} \left(y^{t} ,x^{t} \right)}\right.\] \[ \left. \times \frac{D_{c}^{t} \left(y^{t} ,x^{t} \right)}{D_{c}^{s} \left(y^{s} ,x^{s} \right)} \right]\bullet \left[\frac{D_{c}^{t} \left(y^{t} ,x^{t} \right)}{D_{c}^{t} \left(y^{t} ,x^{t} \right)} \bullet \frac{D_{c}^{s} \left(y^{s} ,x^{s} \right)}{D_{c}^{t} \left(y^{t} ,x^{t} \right)} \right] . \tag{1}\]

The following control variables are mainly chosen in the model design of this paper: cost profit margin (CPM), average enterprise size (AES), foreign investment (FI), and government support (GOV). Among them, Cost Profit Margin (CPM), this indicator can be used to measure the economic effect of cost inputs in the industry. Average Enterprise Size (AES), which is the ratio of the sum of all assets of industrial enterprises above the size to the number of industrial enterprises. The amount of foreign investment (FI), this paper argues that foreign investment activities have two effects on production technology, on the one hand, foreign investment may improve the domestic technological progress through technological spillovers, and will improve the technological progress of production by reducing the degree of monopoly in the domestic market to promote competition and improve the efficiency of resource allocation, such as the competition effect. On the other hand, a large inflow of foreign capital may weaken the industry’s independent R&D and innovation capabilities, so its impact on production technology progress needs to be considered. Government support (GOV) refers to the fact that the government’s financial support can reduce the risks and burdens of R&D investment borne by enterprises, thus stimulating the enthusiasm of enterprises to research and develop new technologies and products, which has a direct impact on improving the technological level and product quality of the manufacturing industry. At the same time, government R&D support is often accompanied by policy guidance, which not only guides enterprises towards the market demand and technological frontier, but also promotes the improvement of enterprises in environmental protection and energy efficiency, thus promoting the overall development of the manufacturing industry in the direction of more efficient and sustainable. In addition, government-supported R&D projects are often highly forward-looking and strategic, leading the development trend of the industry and having a profound impact on the development of the manufacturing industry.

The WTO has clearly proposed that the manufacturing industry should realize high-quality development, and encourage and support the green transformation of the manufacturing industry. This requires the manufacturing industry to achieve sustainable development, after the previous analysis, in the context of the implementation of technological innovation in the manufacturing industry, manufacturing enterprises, shareholders, employees and other stakeholders, by responding to the policy, carry out projects with positive externalities, to send friendly signals to the outside world, highlighting the corporate responsibility and commitment to better access to technological innovation in the manufacturing industry to obtain policy support, to gain a competitive advantage, and to improve their own sustainable development capabilities. Sustainable development capability. Sustainable technological innovation is described by two parts: sustainable product innovation (lnSPI) and process innovation (lnSTI). Among them, sustainable product innovation is measured by the logarithmic form of the ratio of the sales revenue of new products to the total energy consumption of industrial enterprises above large scale, and sustainable process innovation is measured by the logarithmic form of the ratio of the value added of industry to the industrial waste gas emissions.

The measurement of spatial distance between regions is a prerequisite for spatial econometric analysis. Before discussing the nature of spatial correlation, the first step to be taken is to quantify the location factors involved in the sample data and express the spatial interactions between location factors through different spatial weighting matrices, which are constructed on the basis of the “distance” set according to different criteria. The spatial weight matrix is an important vehicle for expressing the spatial correlation with the explanatory variables, and the commonly used spatial weight matrices are the geographic proximity weight matrix, the geographic distance weight matrix and the economic spatial weight matrix.

Before constructing a spatial panel model, the spatial correlation of the research object must be considered. A spatial panel model can be constructed only if there is spatial correlation in the research object. If the variables in neighboring location regions take similar values then it is called the existence of spatial autocorrelation, and when the high and high values are concentrated, the aggregation of low and low values, the spatial autocorrelation is positive. Conversely, when high and low are adjacent, the spatial autocorrelation is negative, and if there is no obvious aggregation pattern between high and low values, and it is a completely random distribution, there is no spatial autocorrelation. There are many methods about measuring the spatial autocorrelation of the data, this paper uses the widely used Moran’s index and Moran’s scatter plot to test the spatial autocorrelation.

Global autocorrelation test

In this paper, the global autocorrelation test of production technology innovation and manufacturing sustainable development is carried out by calculating the global Moran index.Generally, the Moran index takes the value range of (-1,1), and \(\mathrm{\textrm{I}}\)\(\mathrm{\textrm{I}}\)\(\mathrm{>}\)0 indicates a positive correlation, i.e., the high value is clustered with the high value, and the low value is clustered with the low value.\(\mathrm{\textrm{I}}\)\(\mathrm{\textrm{I}}\)\(\mathrm{<}\)0 indicates a negative correlation, i.e., the high value is neighboring to the low value, and the high value is neighboring to the low value if the \(\mathrm{\textrm{I}}\)\(\mathrm{\textrm{I}}\) is close to 0, it indicates that the spatial distribution is random and there is no spatial autocorrelation.

Localized spatial autocorrelation

The first law of geography states that geographic things or attributes in the space. Distributions are correlated with each other, and there are clustered, random, and regular distributions. Spatial autocorrelation analysis is to determine whether a variable is correlated in space, local spatial autocorrelation analysis can further reflect the correlation between each parcel and its neighboring parcels on an attribute.

By constructing spatial econometric model to decompose the direct effect, spillover effect and total effect of production technology innovation on the green sustainable development of manufacturing industry, to provide theoretical and data support for improving the green sustainable development of manufacturing industry. In the process of applying spatial econometric model, an important idea is to introduce the correlation between regions into the model, and according to the different ways of expressing this spatial correlation, the spatial econometric model is mainly divided into three kinds, namely, spatial autoregressive model (SAR), spatial error model (SEM) and spatial Durbin model (SDM).

The data of the research sample of this paper comes from the data of 28 manufacturing sub-industries in each province, and the examination period is 2012-2021. The original data comes from the 2012-2021 Statistical Yearbook of a Province and Industrial Economic Yearbook, and Figure 1 shows the results of descriptive statistical analysis of variables, and the data in the figure indicate the mean value. The data in the figure shows that the mean values of technological progress change (tech), technological efficiency change (effch), product innovation (lnSPI), process innovation (lnSTI), cost profit margin (CPM), average enterprise size (AES), foreign investment (FI), and governmental support (GOV) are 7.55, 4.88, 6.43, respectively, 6.85, 4.69, 4.57, 5.26, and 4.39, and the order of magnitude is change in technological progress (tech)\(\mathrm{>}\)product innovation (lnSPI)\(\mathrm{>}\)process innovation (lnSTI)\(\mathrm{>}\)foreign investment (FI)\(\mathrm{>}\)change in technological efficiency (effch)\(\mathrm{>}\)cost margin (CPM)\(\mathrm{>}\)average size of firms (AES)\(\mathrm{>}\)government support (GOV), detailed outlining the size of the data distribution of the study sample.

In order to deeply analyze the interactions among explanatory variables and to ensure that multicollinearity among these explanatory variables does not adversely affect the accuracy of the panel data analysis, this study implements the variance inflation factor test for models (1) to (2), where model (1) and model (2) represent the imposition of the explanatory variables change in technological advancement (tech), change in technological efficiency (effch). The purpose of this test is to identify and eliminate possible endogeneity problems between the variables, and the results of the variance inflation factor test of the model are shown in Table 1. According to the results of the test in Table 1, it can be observed that the variance inflation factor of all the variables is less than 10, which means that they do not suffer from multicollinearity, and therefore the choice of explanatory variables is initially judged to be appropriate.

| Variable | Model (1) | Model (2) | ||

| VIF | 1/VIF | VIF | 1/VIF | |

| Tech | 2.44 | 0.3497 | ||

| Effch | 2.19 | 0.4375 | ||

| lnSPI | 2.39 | 0.404 | 2.47 | 0.3349 |

| lnSTI | 1.88 | 0.507 | 1.89 | 0.5044 |

| CPM | 1.26 | 0.757 | 1.37 | 0.6914 |

| AES | 1.08 | 0.876 | 1.09 | 0.7537 |

| FI | 2.19 | 0.419 | 1.76 | 0.5495 |

| GOV | 2.07 | 0.433 | 1.85 | 0.5524 |

| Total | 1.9014 | 0.5351 | 1.8029 | 0.5463 |

In order to test the mechanism of the impact of sustainability technology innovation on the high-quality development of the manufacturing industry and to ensure the accuracy and robustness of the empirical results, fixed-effects regression and random-effects regression are carried out for the whole sample, respectively. The selection of panel data model needs to be determined by using F test, LM test and Hausman test in turn, and the test results are shown in Table 2. Based on the data in the table, it can be seen that the P-value of each test statistic is less than 0.01, indicating that all the tests reject the original hypothesis at the 1% significance level, therefore, the results of the benchmark regression in this study should be prioritized to the use of the fixed effects model for empirical testing.

| Project | lnSPI | lnSTI | ||

| Statistics | P value | Statistics | P value | |

| F test | 21.83 | 0.001 | 33.07 | 0.005 |

| LM test | 429.51 | 0.004 | 424.85 | 0.008 |

| Hausman test | 53.52 | 0.006 | 87.15 | 0.003 |

Table 3 demonstrates the analysis of the baseline regression results. Models (3) and (5) are the estimation results of the fixed effects model without adding control variables, respectively. Models (4) and (6) are the estimation results of the models with control variables, fixed effects and random effects, and the R2 of goodness of fit for both fixed effects and random effects is greater than 0.6, indicating that each model is able to explain more than 60% of the variability of the explained variables. Comparing the results of model (3) and model (5), the regression coefficients of technological progress change (tech) and technological efficiency change (effch) on the green sustainable development of manufacturing industry are significant at the 1% level when no control variables are added, which are 0.0644 and 0.0238 respectively, and the regression coefficients are slightly declined after adding control variables but still significant at the 1% level, which are 0.0413 and 0.0146 respectively, and the regression coefficients of control variables are 0.0413 and 0.0146 respectively. After adding the control variables, the regression coefficients slightly decline but are still significant at 1% level, respectively 0.0413 and 0.0146, and the direction of the control variables is the same as the expected direction, indicating that the production technology innovation has a positive impact on the sustainable development of the manufacturing industry. From the different categories of production technology innovation, comparing the impact coefficients of the two, the impact coefficient of technological progress change (tech) is obviously larger, indicating that in the process of promoting the green sustainable development of the manufacturing industry, technological progress change (tech) plays a greater role than technological efficiency change (effch), which may be due to the fact that the pursuit of ecological and social benefits of the sustainability of product innovation, the The reason for this may be that sustainable product innovations that pursue ecological and social benefits, focusing on the integration of environmental protection and sustainability principles, not only enhance the sense of social responsibility of enterprises, but also increase their brand value in the market. In contrast, sustainable process innovations that pursue economic benefits focus on improving cost efficiency and optimizing production processes, and their direct impact on the market and the environment is relatively small. In terms of control variables, the impact coefficients of Cost Profit Margin (CPM) and Foreign Investment (FI) are both positive at the 1% significance level, indicating that increasing the level of Cost Profit Margin (CPM) and Foreign Investment (FI) are both effective in promoting the green sustainable development of the manufacturing industry. The impact coefficients of government support (GOV) and foreign investment (FI) do not have a significant relationship on the green sustainable development of the manufacturing industry, indicating that government support (GOV) and foreign investment (FI) do not have a significant impact on the green sustainable development of the manufacturing industry.

| Variable | Model (3) | Model (4) | Model (5) | Model (6) |

| Tech | 0.0644** (17.845) | 0.0413** (11.505) | ||

| Effch | 0.0238*** (14.932) | 0.0146*** (7.1655) | ||

| CPM | 0.2209*** (5.2731) | 0.4225*** (5.9363) | ||

| AES | -0.0544 (-1.3685) | -0.0218 (-0.4269) | ||

| FI | 2.6675** (5.0854) | 1.5513** (2.4861) | ||

| GOV | -0.0408 (-0.7835) | -0.0675 (-1.1615) | ||

| _cons | 0.0307 (1.0613) | 0.2049*** (5.4541) | 0.4114*** (46.5462) | 0.4168*** (12.7823) |

| R\(^2\) | 0.736 | 0.735 | 0.739 | 0.611 |

The introduction of spatial effect factors into the study of regional economic management is accompanied by the introduction of spatial weight matrices, which represent spatial interactions, into spatial econometric modeling. The spatial weight matrix is an n \(\mathrm{\times}\) n matrix, which usually defines a binary symmetric symmetric matrix to express the neighbor relationship between spatial units at n locations. Write the quantitative relationship between spatial units two by two as a number table usually defines a binary symmetric symmetric matrix to express the neighboring relationship between spatial units at n positions. The quantitative relationship between two spatial units is written as a table of numbers is the spatial weight matrix. In this section, geographic proximity is used as the spatial weight matrix W to test the spatial spillover effect, and the test results are shown in Table 4. From the test results in Table 4, the global Moran index P-value of ten years is less than 0.05, and all of them pass the test, there is a spatial spillover effect of production technology innovation.

| Year | Moran’s I | Z-statistic | P-Value |

| 2012 | 0.374 | 3.127 | 0.009 |

| 2013 | 0.246 | 3.237 | 0.041 |

| 2014 | 0.138 | 2.816 | 0.049 |

| 2015 | 0.386 | 2.969 | 0.039 |

| 2016 | 0.277 | 2.467 | 0.007 |

| 2017 | 0.308 | 2.844 | 0.028 |

| 2018 | 0.211 | 2.737 | 0.006 |

| 2019 | 0.467 | 3.019 | 0.021 |

| 2020 | 0.286 | 3.064 | 0.027 |

| 2021 | 0.408 | 3.306 | 0.033 |

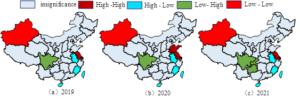

Although the sustainable development capacity of each province does not show obvious agglomeration, but the manufacturing sustainable development capacity of the southernmost coastal area is generally better, roughly showing a trend of gradually decreasing sustainable development capacity from east to west and from coast to inland, so further consider whether there is a local spatial autocorrelation, and the results of spatial local autocorrelation test of the level of sustainable development of the urban manufacturing industry are shown in Figure 2, in which ( a)\(\mathrm{\sim}\)(c) denote 2019\(\mathrm{\sim}\)2021, respectively. Figure 2 shows that in 2019, the level of sustainable development of the manufacturing industry in coastal cities is higher, and this region has a high degree of overlap with the Yangtze River Delta Economic Circle in the four major urban agglomeration development strategies put forward by the state, indicating that the level of sustainable development of the manufacturing industry in the region is higher, while the level of sustainable development of the manufacturing industry in mainland cities is lower. In 2020, the H-H region increased, indicating that the level of sustainable development of the manufacturing industry in the coastal and neighboring provinces has been well developed. And in 2021, the biggest change belongs to the interior cities, with the L-H region increasing from the initial one to three.

Figure 3 shows the Moran scatter plot for 2019-2021. From the results of local clustering in Figure 3, it can be seen that the level of sustainable development of the manufacturing industry in coastal provinces is generally higher, and it is in the leading level in all provinces, and the Moran’1 indexes are all greater than 0, which indicates that the space shows a positive correlation, and the distribution of the provinces in the 2019-2021 is more in the L-L and H-H regions, and the spatial differences among the provinces are small, which can explain that the global autocorrelation does not show a significant clustering of the phenomenon. In summary, the provinces with lower sustainable development capacity are mainly affected by geographic factors, the terrain is hilly or the location is far away from the political and economic center, etc. This will lead to its poor connection with the better developed areas, and it is easy to be affected by the disaster, the economy and other impacts and encounter fluctuations. The southeastern coastal region of the sustainable development of the manufacturing industry is higher, compared with other regions, all aspects of development are at an advanced level. This suggests that, in addition to strengthening the links between regions, regions with low levels of sustainable manufacturing development should also formulate targeted policies to enhance their development strength.

After the research variables pass the spatial autocorrelation test, the above benchmark regression model will be converted into a spatial econometric model, and the spatial econometric model will be tested and analyzed according to the same method described above, which mainly covers the analysis of the regression results and the analysis of the robustness test, and the detailed analysis process will be given in the following.

The regression results of the spatial econometric model are shown in Table 5. Model (7) in Table 5 is the regression result between production technology innovation and green sustainable development of manufacturing industry when no control variables are added, and control variables cost profit margin (CPM), average enterprise size (AES), foreign investment (FI), and governmental support (GOV) are added to model (8)\(\mathrm{\sim}\)model (11) in turn. The regression estimation results show that the coefficients of technological progress change (tech) and technological efficiency change (effch) measured by the composite index of production and technological innovation are 1.718 and 1.644, respectively, which pass the significance test at the 1% significance level, and the regression coefficients of the explanatory variables after adding the control variables are all floating around 2.0, and the regression coefficients of the explanatory variables float around 2.0, which are not significant in controlling the other influences affecting the capacity for sustainable development. Controlling for other factors affecting the sustainable development ability, production technology innovation still significantly improves the sustainable development ability of the manufacturing industry, that is to say, it indicates that the sustainable development level of the manufacturing industry will be further improved with the increase in the degree of production technology innovation. It can be seen that technological innovation is indeed a key factor in promoting the improvement of the sustainable development level of the manufacturing industry, and improving the level of technological innovation is conducive to the enhancement of the sustainable development level of the manufacturing industry, as well as there is room for upgrading the status.

| Explanatory variable | Explained variable | ||||

| Model (7) | Model (8) | Model (9) | Model (10) | Model (11) | |

| Tech | 1.718*** (0.0771) | 1.374*** (0.023) | 1.383*** (0.014) | 1.384*** (0.015) | 1.397*** (0.008) |

| Effch | 1.644*** (0.034) | 0.105*** (0.013) | 0.118*** (0.018) | 0.124*** (0.027) | 0.137*** (0.036) |

| CPM | 0.097*** (0.041) | 0.0101*** (0.033) | 0.0115*** (0.023) | 0.0123*** (0.042) | |

| AES | -0.021*** (0.027) | -0.028*** (0.014) | -0.031*** (0.011) | ||

| FI | -0.033*** (0.009) | -0.047** (0.005) | |||

| GOV | -0.062** (0.001) | ||||

| _cons | 0.377** (0.002) | -0.637*** (0.064) | -0.644*** (0.107) | -0.707*** (0.116) | -0.753*** (0.042) |

| Time fixed effect | Controls | Controls | Controls | Controls | Controls |

| Individual fixation effect | Controls | Controls | Controls | Controls | Controls |

| R\(^2\) | 0.755 | 0.826 | 0.827 | 0.828 | 0.831 |

In order to test the robustness of the empirical results, this paper transforms the production technology innovation indicators by replacing the independent variables, reflecting the production technology innovation from a single indicator. In this paper, we choose the index of invention patent application authorization in each province and city (autonomous region) to measure the development level of production technology innovation, and eliminate the influence of the quantitative outline, and carry out logarithmic processing, respectively, which is recorded as lnzl, and then carry out the regression of the panel to test whether the influence of product innovation (lnSPI) and process innovation (lnSTI) on the green sustainable development of the manufacturing industry is still robust, and the results of the robustness test are shown in Table 6. . By comparing the robustness test regression results with the fixed effect regression results, whether using product innovation (lnSPI), process innovation (lnSTI) or using the single indicator of invention patent application authorization (lnzl) to measure production technology innovation, the impact on the sustainable development of manufacturing industry passed the significance test at the 1% level, showing a significant positive impact. The regression coefficients of technological progress change (tech), technological efficiency change (effch) and product innovation (lnSPI) are 1.704 and 1.753 respectively, while the regression coefficient of the number of invention patent application authorization and product innovation (lnSPI) is 0.105, which shows that the change of technological progress (tech) and technological efficiency change (effch), are more in line with the actual situation. The comprehensive indicator is to consider a variety of factors, compared with a single indicator of the measurement is more comprehensive. In conclusion, the fixed effects regression results are robust.

| Variable | Lnzl(1) | Effch(2) | Tech(3) |

| lnSPI | 0.105***(0.012) | 1.704***(0.046) | 1.753***(0.037) |

| lnSTI | 0.093***(0.039) | 1.113***(0.042) | 1.237***(0.025) |

| _cons | -0.438**(0.0208) | 0.377**(0.005) | 0.385**(0.002) |

| Time fixed effect | Controls | Controls | Controls |

| Individual fixation effect | Controls | Controls | Controls |

In this paper, the sub-industry data of 28 manufacturing industries in each province are selected as research samples, and the explanatory variables, explanatory variables, control variables and corresponding measurement methods of the model are set. After spatial autocorrelation detection, the spatial measurement model is constructed to systematically explore the role of production technology innovation on the sustainable development of manufacturing industry.

It is found that the variables have the following relationships, technological progress change (tech) \(\mathrm{>}\) product innovation (lnSPI) \(\mathrm{>}\) process innovation (lnSTI) \(\mathrm{>}\) foreign investment (FI) \(\mathrm{>}\) technological efficiency change (effch) \(\mathrm{>}\) cost profit margin (CPM) \(\mathrm{>}\) average enterprise size (AES) \(\mathrm{>}\) governmental support (GOV), and they do not have multicollinearity.

Without adding control variables, the regression coefficients of technological progress change (tech) and technological efficiency change (effch) on the green sustainable development of manufacturing industry are significant at the 1% level, which are 0.0644 and 0.0238 respectively, and the regression coefficients after adding control variables are slightly declined but are still significant at the 1% level, which are 0.0413 and 0.0146, which indicate that regardless of adding the control variables, the regression coefficients of sustainability technological innovation on the green sustainability development of manufacturing industry are significant at the 1% level. Control variables, sustainability technology innovation on the sustainable development of the manufacturing industry as a whole shows a positive impact.

Introducing the spatial effect factor, the P-values of the global Moran index for the ten-year period from 2012 to 2021 are all less than 0.05, which all pass the test, indicating the existence of spatial spillover effects of production technology innovation. Further local autocorrelation tests yielded that the level of sustainable development of manufacturing industry in coastal provinces is generally high and is at the leading level in all provinces, and the Moran’1 indexes are all greater than 0, i.e., there is a positive spatial correlation, and the L-H region of the mainland cities has increased from the initial one to three by 2021.

After passing the spatial autocorrelation test, the above benchmark model is automatically converted into a spatial econometric model, and the regression coefficients of technological progress change (tech), technological efficiency change (effch) and product innovation (lnSPI) are 1.704 and 1.753 respectively, however, the regression coefficient of the number of invention patent application authorization and the change of technological progress (tech) is 0.105, and based on the Based on the results of regression coefficient comparison, it can be seen that technological progress change (tech) and technological efficiency change (effch) are more influential, which is more in line with the goal of green and sustainable development of manufacturing industry.

Chang, A. Y., & Cheng, Y. T. (2019). Analysis model of the sustainability development of manufacturing small and medium-sized enterprises in Taiwan. Journal of cleaner production, 207, 458-473.

Yong, J. Y., Yusliza, M. Y., Ramayah, T., Chiappetta Jabbour, C. J., Sehnem, S., & Mani, V. (2020). Pathways towards sustainability in manufacturing organizations: Empirical evidence on the role of green human resource management. Business Strategy and the Environment, 29(1), 212-228.

Moldavska, A., & Welo, T. (2017). The concept of sustainable manufacturing and its definitions: A content-analysis based literature review. Journal of Cleaner Production, 166, 744-755.

Khan, I. S., Ahmad, M. O., & Majava, J. (2021). Industry 4.0 and sustainable development: A systematic mapping of triple bottom line, Circular Economy and Sustainable Business Models perspectives. Journal of Cleaner Production, 297, 126655.

Saleem, H., Khan, M. B., & Mahdavian, S. M. (2022). The role of green growth, green financing, and eco-friendly technology in achieving environmental quality: evidence from selected Asian economies. Environmental Science and Pollution Research, 29(38), 57720-57739.

Silvestre, B. S., & Ţîrcă, D. M. (2019). Innovations for sustainable development: Moving toward a sustainable future. Journal of cleaner production, 208, 325-332.

Wu, Y., & Tham, J. (2023). The impact of environmental regulation, Environment, Social and Government Performance, and technological innovation on enterprise resilience under a green recovery. Heliyon, 9(10), 1213.

Jayashree, S., Hassan Reza, M. N., Malarvizhi, C. A. N., Maheswari, H., Hosseini, Z., & Kasim, A. (2021). The impact of technological innovation on industry 4.0 implementation and sustainability: an empirical study on Malaysian small and medium sized enterprises. Sustainability, 13(18), 10115.

Yang, X., Guo, Y., Liu, Q., & Zhang, D. (2022). Dynamic Co-evolution analysis of low-carbon technology innovation compound system of new energy enterprise based on the perspective of sustainable development. Journal of Cleaner Production, 349, 131330.

Álvarez Jaramillo, J., Zartha Sossa, J. W., & Orozco Mendoza, G. L. (2019). Barriers to sustainability for small and medium enterprises in the framework of sustainable development—L iterature review. Business Strategy and the Environment, 28(4), 512-524.

Shahzad, M., Qu, Y., Javed, S. A., Zafar, A. U., & Rehman, S. U. (2020). Relation of environment sustainability to CSR and green innovation: A case of Pakistani manufacturing industry. Journal of cleaner production, 253, 119938.

Ikram, M., Zhou, P., Shah, S. A. A., & Liu, G. Q. (2019). Do environmental management systems help improve corporate sustainable development? Evidence from manufacturing companies in Pakistan. Journal of Cleaner Production, 226, 628-641.

Roscoe, S., Subramanian, N., Jabbour, C. J., & Chong, T. (2019). Green human resource management and the enablers of green organisational culture: Enhancing a firm’s environmental performance for sustainable development. Business Strategy and the Environment, 28(5), 737-749.

Zhang, F., & Zhu, L. (2019). Enhancing corporate sustainable development: Stakeholder pressures, organizational learning, and green innovation. Business Strategy and the Environment, 28(6), 1012-1026.

Yusliza, M. Y., Yong, J. Y., Tanveer, M. I., Ramayah, T., Faezah, J. N., & Muhammad, Z. (2020). A structural model of the impact of green intellectual capital on sustainable performance. Journal of Cleaner Production, 249, 119334.

Kuo, T. C., & Smith, S. (2018). A systematic review of technologies involving eco-innovation for enterprises moving towards sustainability. Journal of Cleaner Production, 192, 207-220.

Henao, R., Sarache, W., & Gómez, I. (2019). Lean manufacturing and sustainable performance: Trends and future challenges. Journal of cleaner production, 208, 99-116.

Bag, S., Gupta, S., & Kumar, S. (2021). Industry 4.0 adoption and 10R advance manufacturing capabilities for sustainable development. International Journal of Production Economics, 231, 107844.

Bag, S., & Pretorius, J. H. C. (2022). Relationships between industry 4.0, sustainable manufacturing and circular economy: proposal of a research framework. International Journal of Organizational Analysis, 30(4), 864-898.

Kamble, S., Gunasekaran, A., & Dhone, N. C. (2020). Industry 4.0 and lean manufacturing practices for sustainable organisational performance in Indian manufacturing companies. International Journal of Production Research, 58(5), 1319-1337.

de Sousa Jabbour, A. B. L., Jabbour, C. J. C., Foropon, C., & Godinho Filho, M. (2018). When titans meet–Can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? The role of critical success factors. Technological Forecasting and Social Change, 132, 18-25.

Li, G., Wang, X., Su, S., & Su, Y. (2019). How green technological innovation ability influences enterprise competitiveness. Technology in Society, 59, 101136.

Bradu, P., Biswas, A., Nair, C., Sreevalsakumar, S., Patil, M., Kannampuzha, S., … & Gopalakrishnan, A. V. (2022). Recent advances in green technology and Industrial Revolution 4.0 for a sustainable future. Environmental science and pollution research international, 1, 1982.

Qian, J., Chen, C., & Zhong, Y. (2022). Environmental regulation and sustainable growth of enterprise value: mediating effect analysis based on technological innovation. Sustainability, 14(21), 13723.