The use of a variety of high-performance fiber fabrics to manufacture lightweight and high-strength composite materials is the development trend of fabrics. In this paper, based on the principle of integrated design of structural properties of composites, the high-strength and high-modulus aramid fibers and low-density and high-toughness PBO fibers are used as reinforcing materials, and carbon fiber materials are utilized as modified materials. The CF-ANF-PBO super hybrid 3D composites with various laminated structures were prepared by RTM molding process. The fabric composites with different hybrid structures were designed according to the volume fraction of ANF/PBO, and the mechanical properties of the composites with different hybrid structures were investigated. The results showed that when the volume fraction of ANF/PBO reached 100%, the tensile modulus and strength of the composites were the largest in the unmodified condition, which were 68.81 GPa and 543.02 MPa, respectively, and the tensile modulus and strength became 73.52 GPa and 636.82 MPa after modification with carbon fibers, and the overall improvement of tensile modulus and tensile strength properties were 6.8% and 17.27%, respectively. The It can be seen that the incorporation of carbon fibers significantly improves the properties of aramid and PBO fiber composites.

Premium fabric fabrics are highly valued for their unique delicate texture and high level of craftsmanship. Premium fabric fabrics are widely used in fashion design, home decoration and other fields [1,2]. Fine texture, high quality, durability, comfort and other characteristics of fine fabric fabrics, the texture and quality of fine fabric fabrics are affected by the choice of fibers, common fiber materials include silk, wool, aramid, carbon and PBO fibers, etc., and the selection of appropriate fiber materials is very important to improve the texture of fabrics [3-5].

Carbon fibers and aramids are among the materials considered to have the greatest potential and promise. High-tech fibers are fiber materials with outstanding properties and prospects for a wide range of applications [6]. Carbon fiber is a kind of fiber material composed of carbon element, which has the characteristics of light weight, high strength, high modulus and corrosion resistance. Due to its excellent performance, carbon fiber has been widely used in aerospace, construction and other fields [7,8]. Aramid is a kind of fiber material composed of aromatic polymers with heat resistance, chemical resistance and excellent mechanical properties, which are widely used in protective clothing, electronic devices, etc. [9]. PBO fibers are rigid rod-shaped polymers composed of benzene and aromatic heterocyclic rings, and the molecular chains form a highly oriented, two-dimensional ordered structure during the liquid crystal spinning process. Due to its unique spatial resistance effect and conjugation effect, the molecular chains of PBO fibers can form a very close stacking [10,11]. The most significant feature of PBO fibers is that the macromolecular chains, crystals and microfibrils are almost completely oriented along the axial direction of the fibers, forming a highly oriented ordered structure. The strength of PBO fibers is higher than that of aramid fibers, which is more than 10 times of that of steel wires, and it can be higher than that of carbon fibers [12-14].

Aramid is a high-performance fiber, with high strength, high modulus, excellent thermal and chemical stability and many other advantages of its applications are quite wide, such as aramid bulletproof vests, helmets, spaceships, airplanes, and other matrix materials. Literature [15] examined the market for aramid fibers including firefighting clothing, etc., introduced an approach to the preparation and utilization of pairs and inter-aramid fibers, and used a semi-industrial plasma device to prepare test samples, strength and elongation at break as an indicator to determine the performance of the fabric of the protective clothing, and finally the test results are discussed. Literature [16] acknowledged the outstanding high strength and modulus of aramid fibers and reviewed the developing applications of aramid polymers in the production of mature and commercial high-performance fibers, analyzing the relationship between their structural properties and the prospects for their application. Literature [17] proposed polyimide as a material for arc protective clothing based on the fact that aramid produces toxic gases under high temperature combustion. The heat resistance of polyimide and aramid was compared by using molecular dynamics simulation, and the protective performance of the materials was tested by constructing an electric arc test device, and the results showed that polyimide as a material for arc protective clothing is beneficial to improve the protective performance. Literature outlined the properties, applications and importance of aramid fibers, and pointed out a way to improve the performance of aramid fiber composites, i.e., to enhance the interfacial adhesion between the aramid fibers and the matrix.

Carbon fiber is a kind of fiber made of carbon raw material melted or made by a special process, the advantages of ultra-low transverse tensile strength, tensile strength, abrasion resistance, and low density make it widely used in the fields of home, clothing, and sporting goods. Literature [18] provides a comprehensive overview of the basic principles, properties, development and applications of carbon fiber textiles, providing professional and reliable knowledge and theory for researchers in this field. Literature [19] developed carbon fiber reinforced composites with orthotropic structure and compared their performance with laminated structural composites. Through a series of comparative experiments and analyses, it is concluded that orthogonal structure composites are conducive to improving the overall performance of carbon fiber composites and have important guiding value for the development and application of their products. Literature [20] aims to apply modal tests to predict the in-plane bending fatigue life of carbon fiber reinforced plastic laminates under different fiber orientations, using FFTanalyzer to establish the modal characteristics and determining that the fatigue life is affected by frequency. The results of the study verified that modal experiments are effective testing methods that can be used in the fatigue life prediction of composite materials. Literature [21] describes various polymer matrix composites loaded with carbon fibers, highlighting the structurally important role of these materials, aiming to present full-spectrum information related to carbon fiber-based polymer composites and discussing the properties of carbon fibers, processing and manufacturing of composites.

As a super performance fiber in the 21st century, PB0 has very excellent physical and mechanical properties and chemical properties. PB0 fiber has four super special properties, namely strength, modulus, heat resistance and flame resistance, and is widely used in aerospace, military protection and sports equipment. Literature [22] examined the structure and properties of orthogonal three-dimensional woven fabrics with aramid and PBO fibers, and compared them with two-dimensional woven fabrics in comparative experiments, and the results indicated that the overall performance of three-dimensional woven fabrics was better than that of two-dimensional woven fabrics. Literature [23] explored the effects of y-ray irradiation, coupling agent acid treatment and combined treatments on the filament strength of PBO fibers and investigated their tensile strength using Weibull analysis. It was emphasized that a proper combination of different treatments could better retain the excellent mechanical properties of PBO fibers. Literature [24] reviewed the effects produced by different temperatures, time and stress on the surface and physicochemical properties of PBO fibers based on scanning electron microscopy analysis and single fiber stretching. The results showed that there was no significant change in the tensile strength of PBO before 600 degrees Celsius, but there was a significant decrease at 650 degrees Celsius, while the heat treatment also caused a rougher fiber surface. Literature [25] treated PBO fibers under different conditions using NaOH and KMnO4 solutions. Scanning electron microscopy and optical microscopy were used to characterize the changes in structure and properties, and the results of the study revealed that the treatment of PBO fibers with KMnO4 and NaOH exhibited different degrees of corrosion and cracking.

In this paper, based on the theory of hybrid composites, CF-ANF-PBO super hybrid 3D composites with different ANF/PBO volume fractions were constructed under RTM molding process by using aramid and PBO fibers as reinforcements and carbon fiber materials as modifiers, which were braided by a four-step 3D braiding machine. Various equipments such as optical electron microscope, Fourier transform infrared spectroscopy, UV-visible near-infrared absorption spectroscopy, universal tensile tester, and electrochemical workstation were used to characterize the mechanical properties of CF-ANF-PBO composites. The composites with five hybrid structures each before and after modification were prepared and tested in tensile and impact, and the differences in tensile and impact properties of different hybrid structures were analyzed through the data.

Composites made of two or more reinforcements reinforcing the same matrix or multiple matrices on a macroscopic scale are called hybrid fiber composites. In most cases, hybridization is used to obtain a new class of materials that retain the advantages of their constituent materials and are expected to overcome some of their limitations. The phenomenon of deviation of certain properties from the law of mixing in hybrid composites is called hybrid effect (positive hybrid effect, negative hybrid effect). For this reason, this paper proposes a CF-ANF-PBO composite fabric material consisting of carbon fibers (CF), aramid fibers (all-aromatic polyamide, ANF), and poly(p-phenylene pro-benzodioxazole) (PBO) fiber composite, woven. Using the three fiber materials, such as flame retardant, high temperature resistance, high thermal insulation and other functional characteristics, it is hoped that the material will be used in aerospace protective clothing, thermal insulation protective clothing and other advanced fabrics.

The reinforcing fibers used were T700SC-12K carbon fibers, Kevlar 49 \(\mathrm{\times}\) 4 co-stranded para-aramid fibers, and PBO fabric fibers with homemade specifications of 2/1 twill. The performance parameters of the three fibers are shown in Table 1, and the densities of the three fibers are 1.85, 1.56, and 2.52\({\rm g}\cdot {\rm cm}^{-3}\), respectively, with the line density of T700SC-12K carbon fiber reaching 900.00 tex.

| Materials | Carbon fiber (CF) | Aramid fiber (ANF) | PBO fiber |

| Card number | T700SC-12K | Kevlar 49 | 2/1 Twill |

| Density/\(\rm g\cdot {\rm cm}^-3 \) | 1.85 | 1.56 | 2.52 |

| Line density /tex | 900.00 | 185.00 | 125.00 |

| Tensile strength/MPa | 5200 | 2800 | 1054 |

| Tensile modulus/GPa | 237 | 131 | 98 |

| Breaking elongation rate (Total elongation rate)/% | 1.0 | 2.6 | 3.2 |

The 3D woven structure of CF-ANF-PBO composite fabric material has the flexibility of design, and there are more parameters that can be controlled during the design of 3D woven preforms, which mainly include the weaving structure (3D4d, 3D5d, 3D6d, and 3D7d), the blending method (intra-bundle blending, group blending), the weaving process parameters (weaving angle, knob length, knob width, fiber volume content and shape size ), yarn type (single fiber, blended fiber), and blend volume ratio. During the design process, different parameters can be varied while using different base materials to meet different performance requirements.

Braided structure

Compared to carbon fiber, aramid fiber, and PBO fiber monomaterials, CF-ANF-PBO hybrid fiber composites are made to compromise the properties (tensile strength, tensile modulus, and elongation at break). Therefore, it is proposed to design three-dimensional five-way braided structural composites with braided yarns of aramid fibers, axial yarns of carbon fibers, and transverse yarns of PBO fiber blend.

Blending method

Non-metallic carbon fibers, aramid fibers and PBO fibers were blended using group blending combined with in-bundle blending. Four types of super hybrid composites with carbon fibers for the axial yarns, CF-PBO in-bundle hybrid and ANF-PBO in-bundle hybrid for the braiding yarns, and CF-PBO in-bundle hybrid and ANF-PBO in-bundle hybrid for the axial yarns, and aramid fibers for the braiding yarns were designed and prepared.

Parameters of braiding process

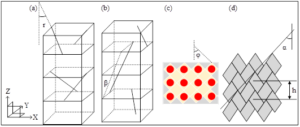

According to the different distribution states of the yarns in the precast body as shown in Figure 1, where the braiding angle can be categorized into internal braiding angle 1(a), surface braiding angle 1(b), braiding angle 1(c) and 1(d), etc.. \(\gamma\) is the internal braiding angle (the angle between the internal braiding yarns and the molding direction of the prefabricated body), \(\beta\) is the surface braiding angle (the angle between the projection of the braiding yarns on the surface of the prefabricated body on the surface and the molding direction). \(\psi\) is the angle between the projection of the braided yarns on the cross-section and the thickness direction of the precast body, and \(\alpha\) is the braiding angle (the angle between the direction of the braided texture formed by the arrangement of adjacent inclined braided yarns on the surface and the molding direction of the precast body).

The fiber volume as a percentage of the entire volume of the prefabricated body is called the fiber volume content, which is a parameter that reflects the degree of densification of the fabric. Within a certain range, the higher the index, the better the performance of the composite material.

CF-ANF-PBO super hybrid three-dimensional knitted preforms are knitted using a four-step three-dimensional knitting machine. The yarns are arranged according to the preset number of rows and rows of carriers and the number of yarn combinations, and the yarns are interwoven in space to form a super hybrid 3D knitted precast body by the four-step knitting process with the movement of the carriers [26].

The quality of the precursor forming process is not only related to the knitting process parameters (knitting angle, knurl length and fiber volume), but also to the friction and abrasion between the hybrid fibers, as well as to the damage to the fibers during manual handling. Carbon fibers are prone to brittle fracture during braiding, while the mixing process with aramid fibers leads to serious pilling of aramid fibers due to friction and abrasion between the fibers, which extremely affects the quality of the braided precursor. At the same time, PBO fibers have high residual torque and are easily curled and twisted, which makes it easy to break the head during weaving. Therefore, it is necessary to regulate the fibers and preforms before, during and after weaving.

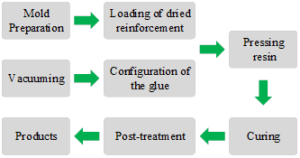

Resin transfer molding (RTM) molding technology has the characteristics of low product porosity, low environmental pollution and near-net-size molding, so the RTM molding process was chosen in this project as shown in Figure 2 for the molding and preparation of CF-ANF-PBO composites.

The practical steps for composite curing of CF-ANF-PBO super hybrid 3D woven composites are as follows:

Fabric drying

Put the cut fabric into the oven with the temperature set at 60\(\mathrm{{}^\circ}\)C and the time set at 5 hours.

Mold cleaning

The mold will be cleaned and treated so that its surface is free of impurities to ensure the quality of the molded composite material.

Apply mold release agent

Beneficial to the composite material after molding and mold separation as well as to ensure the quality of composite material molding, this process is generally carried out twice coating.

Fabric cutting

The effective size of each piece of fabric is 250mm \(\mathrm{\times}\) 20mm, and the actual cutting size is 280mm \(\mathrm{\times}\) 25mm, which is cut and weighed.

Gluing

Gluing temperature 45\(\mathtt{{}^\circ\!{C}}\), gluing pressure 0.2\(\mathrm{\sim}\)0.6MPa, gluing time 3\(\mathrm{\sim}\)5 hours.

Curing

TDE86# resin system is selected, according to a certain curing system for its composite molding. Vacuum is carried out in this process, and resin flow is used to infiltrate the preform.

The volume fractions of ANF/PBO were set to 0%, 25%, 50%, 75% and 100%, respectively, and the preparation of different hybrid structural composites was achieved by controlled addition of CF materials through RTM process. Finally, a total of five pre-fabricated specimens of A1, A2, A3, A4, and A5, as well as five pre-fabricated specimens after CF modification were obtained.

The basic information of other categories of chemical reagents used in this paper is shown in Table 2.

| Reagent name | Purity | Producer |

| Anhydrous ethanol (CH\(_3\)CH\(_2\)OH) | Analytically pure | Tianjin Fuyu Fine Chemical |

| Dimethyl sulfoxide (DMSO) | Analytically pure | Aladdin’s reagent |

| Acetone (CH\(_3\)COCH\(_3\)) | Analytically pure | Tianjin Tianli Chemical reagent |

| 98% concentrated sulfuric acid (H\(_2\)SO\(_4\)) | Analytically pure | Harbin chemical reagent |

| Phosphoric acid (H\(_3\)PO\(_4\)) | Analytically pure | Harbin chemical reagent |

| Hydrochloric acid (HCI) | Analytically pure | Sinopharm Group |

| Hydrogen peroxide (H2O2) | Analytically pure | Aladdin’s reagent |

| Polyvinyl alcohol (PVA) | Analytically pure | Aladdin’s reagent |

| Potassium tert-butanol | Analytically pure | Aladdin’s reagent |

| Potassium hydroxide (KOH) | Analytically pure | Harbin chemical reagent |

| Glacial acetic acid 98%(CH\(_3\)COOH) | Analytically pure | Harbin chemical reagent |

| Concentrated nitric acid (HNO\(_3\)) | Analytically pure | Harbin chemical reagent |

| Methanol (CH\(_3\)OH) | Analytically pure | Jing pure chemical reagent factory |

| Sodium styrene sulfonate (C\(_8\)H\(_7\)O\(_3\)SNa) | Analytically pure | Sigma Aldrich Corporation |

| Deionized water (H\(_2\)O) | Self-control |

Specific information about the various equipment and instruments used in this paper is shown in Table 3. The major ones include, Optical Electron Microscope, Fourier Transform Infrared Spectroscopy, UV-visible Near Infrared Absorption Spectroscopy. Test equipment including universal tensile tester, electrochemical workstation were used to characterize the mechanical properties of CF-ANF-PBO composites. Including the scanning electron microscope (SEM) produced by FEI company in the United States, X-ray photoelectron spectroscopy (XPS) produced by Thermo Fisher company in the United States, Fourier transform infrared spectroscopy (FTIR) produced by Bruker company in Germany, vacuum drying oven and UV-visible spectroscopy produced by Beijing Pudian company, and so on.

| Name of experimental equipment | Model number | Producer |

| Scanning electron microscope (SEM) | HeliosNanolab800i | American FEI |

| Transmission electron Microscope (TEM) | JEOL2100 | Nippon Electronics |

| Laser confocal Raman spectroscopy | inVia | Renishaw, UK |

| X-ray photoelectron Spectroscopy (XPS) | ESCALAB 250Xi | Thermo Fisher, USA |

| X-ray diffractometer (XRD) | X’ Pert PRO | Panalytical, Netherlands |

| Universal mechanical testing machine | 5954 | Instron, USA |

| Ultrasonic cleaning machine | DYY-6C | DongYuan, China |

| Synchronous heat analyzer | STA452F3 | Endurance, Germany |

| Thermo-mechanical performance analyzer | Q900 | TA Instrument, USA |

| Fourier Infrared Spectrometer (FTIR) | TENSOR 27 | Brooke, Germany |

| Vacuum drying oven | DZF-6050 | PuXi instrument, China |

| Desktop centrifuge | TG16 | LuXiang, China |

| Four-point probe | HPS2526 | Haier, China |

| Electrochemical workstation | PARSTAT 4200 | Princeton, USA |

| Specific Surface Area Test (BET) | ASAP 2023 | Quanta Chrome, USA |

| Ultraviolet-visible spectrometer | TU-1815 | PuXi instrument, China |

Scanning Electron Microscope (SEM)

In order to observe the morphology and size of the prepared CF-ANF-PBO composite fibers, films and gels, the HeliosNanolab800i scanning electron microscope produced by FEI was selected to characterize and analyze the materials from the microstructure and morphology. For the dispersion can be directly diluted and dropped on the surface of the aluminum sheet to wait for the solvent to evaporate and then fixed to the sample stage with conductive adhesive for observation, for the fiber and film samples need to be cut into small pieces of the appropriate size and paste on the conductive adhesive. Hydrogel samples were freeze-dried and then cut into small pieces. All samples need to be sprayed with gold before testing in order to facilitate observation.

Transmission Electron Microscope (TEM)

In this paper, a Japanese JEOL2100 transmission electron microscope was used to observe the microscopic morphology of CF-ANF-PBO composite fibers. The pre-prepared dispersion was diluted before the test, and 1-2 drops of the diluted dispersion were taken on the copper mesh, which was put into the transmission electron microscope for observation after the dispersion was completely evaporated and dried. The accelerating voltage was 200kV and the magnification was 1-600,000 times.

X-ray diffraction analysis (XRD)

X-ray diffraction is an analytical tool used to characterize the crystal structure and physical phase of materials. This experiment was used to analyze the changes in the crystalline structure of the material before and after the preparation of CF-ANF-PBO composites, as well as the post-treatment process. A diffractometer of model X’ Pert PRO from Panalytical, Netherlands was used, and the rays were derived from Cu target \({\rm K\alpha }\) rays (wavelength 0.1541 nm).

Fourier infrared spectroscopy analysis (FTIR)

In this paper, TENSOR 27 model FTIR spectroscopy was used to analyze the functional groups on the surface of the material and to characterize the interaction relationship among the three fiber materials, CF, ANF and PBO. A small amount of sample was taken and ground with a certain amount of potassium bromide powder into a mold and pressed in a tablet press to characterize the infrared transmission and absorption of the test samples in the range of 500-5000\({\rm cm}^{{\rm -1}}\).

Thermogravimetric analysis

In this experiment, a thermogravimetric analyzer model STA452F3 from NETZSCH, Germany, was used to determine the mass of the prepared CF-ANF-PBO composites in relation to the temperature change. The thermal weight loss of the samples was tested in the range of 30-600 \(\mathrm{{}^\circ}\)C in a nitrogen atmosphere with a temperature increase rate of 10 \(\mathrm{{}^\circ}\)C/s. The composites were analyzed by using the STA452F3 model thermal gravimetric analyzer from NETZSCH, Germany. The focus is on the weight loss of different CNTs mass fractions in the composites as well as the thermal decomposition temperature of the composites, which is used to analyze the heat resistance of the materials.

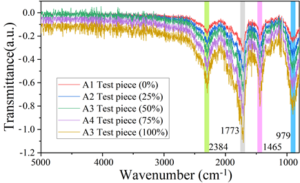

Figure 3 shows the IR spectral test results of five pre-specimens of CF-ANF-PBO super hybrid 3D composites of A1, A2, A3, A4 and A5. Their volume fractions of ANF/PBO were set as 0%, 25%, 50%, 75% and 100%, respectively. The results are as follows:

The CF-ANF-PBO composite has four typical characteristic absorption peaks, which are the bending vibration of O-H at 979\({\rm cm}^{{\rm -1}}\), the stretching vibration peak of C-O at 1465\({\rm cm}^{{\rm -1}}\), the bending vibration peak of C-H at 1773\({\rm cm}^{{\rm -1}}\) in \({\rm -CH}_{{\rm 2}}\) and -CH3, and the stretching vibration peak of C-H at 2384\({\rm cm}^{{\rm -1}}\) in \({\rm -CH}_{{\rm 2}}\) and \({\rm -CH}_{3}\), respectively.

The four typical characteristic absorption peaks of ANF material in IR spectroscopy test correspond to N-H stretching vibration peak, C-O-H vibration peak, N-H bond bending vibration peak, and benzene ring C-C bonding peak, respectively.The first peak of PBO material in the four typical characteristic absorption peaks corresponds to Si-O, followed by \({\rm SiO}_{{\rm 2}}\) particles, elemental Si, and and covalent oxides in the form.

The CF-ANF-PBO hyperblended 3D composites have four characteristic peaks from volume fraction 0 to 100% increase. It shows that no new characteristic peaks appear in the CF-ANF-PBO material, and the preparation process of this composite is purely physical bonding without chemical reaction.

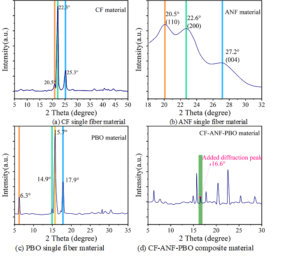

X-ray diffraction spectroscopy was used to analyze the crystalline structures of three single fiber materials, CF, ANF and PBO, and CF-ANF-PBO super hybrid 3D composites as shown in Figure 4. The results are as follows:

The crystalline structure of CF material is shown in Figure 4(a), with three diffraction peaks appearing at \({\rm 2\theta }\)=20.5\(\mathrm{{}^\circ}\), 22.3\(\mathrm{{}^\circ}\), and 25.3\(\mathrm{{}^\circ}\) for carbon fibers.

The crystalline structure of ANF material is shown in Figure 4(b), with aramid fibers having (110), (200), and (400) crystal planes at \({\rm 2\theta }\)=20.5\(\mathrm{{}^\circ}\), 22.6\(\mathrm{{}^\circ}\), and 28.5\(\mathrm{{}^\circ}\), with the presence of three diffraction peaks.

Figure 4(c) shows the results of analyzing the diffraction spectra of the PBO material, and it was found that four diffraction peaks appeared at \({\rm 2\theta }\)=6.3\(\mathrm{{}^\circ}\), 14.9\(\mathrm{{}^\circ}\), 15.7\(\mathrm{{}^\circ}\), and 17.9\(\mathrm{{}^\circ}\).

The X-ray diffraction spectra of CF-ANF-PBO superblended 3D composites were analyzed as shown in Figure 4(d).The CF-ANF-PBO film was coated with CF under the melting of CF and the microcapsule structure was obtained after cooling. This process underwent the recrystallization of CF and PBO, which led to the complexity of the crystalline structure, and in addition to the original diffraction peaks of the three materials, a new diffraction peak appeared at \({\rm 2\theta }\)=16.6\(\mathrm{{}^\circ}\).

The conclusion shows that the crystalline shape of CF and PBO materials changed during the preparation of CF-ANF-PBO superhybrid 3D composites, but the enthalpy can be maintained to a certain extent, which has less influence on their actual properties.

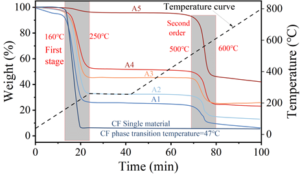

A thermogravimetric analyzer model STA452F3 from NETZSCH, Germany, was used to determine the mass of the prepared CF-ANF-PBO composites in relation to the temperature change. Figure 5 shows the TGA curves of three single fiber materials, CF, ANF and PBO, and CF-ANF-PBO super-blended 3D composites, by which the TGA curves can be used to describe the thermal stability properties and core content of these materials. The results are as follows:

The TGA curves of CF monomaterials and CF-ANF-PBO composite films show significant weight loss in the range of 160\(\mathrm{{}^\circ}\)C to 250\(\mathrm{{}^\circ}\)C, which can be attributed to the decomposition of carbon fiber materials.

Unlike pure CF, the TGA curves of CF-ANF-PBO composites went through two stages of thermal decomposition, with the first weight loss occurring in the range of 160\(\mathrm{{}^\circ}\)C\(\mathrm{\sim}\)250\(\mathrm{{}^\circ}\)C, which corresponded to the thermal decomposition of CF, and the second stage of decomposition in the range of 500\(\mathrm{{}^\circ}\)C\(\mathrm{\sim}\)600\(\mathrm{{}^\circ}\)C, which could be attributed to the decomposition of ANF. The ANF film, which had an excellent thermal stability, started to decompose only at around 550\(\mathrm{{}^\circ}\)C, and basically decomposed completely at 600\(\mathrm{{}^\circ}\)C. It basically decomposes completely at 600\(\mathrm{{}^\circ}\)C.

PBO monomaterials basically do not participate in the decomposition between 0 and 800\(\mathrm{{}^\circ}\)C, with almost no mass loss.

The CF-ANF-PBO composite film has almost no mass loss at the phase transition temperature of CF (47\(\mathrm{{}^\circ}\)C), and the decomposition temperature is much higher than the phase transition temperature.

The conclusion shows that the CF-ANF-PBO composites have good thermal stability and high core cladding ratio at operating temperature. And it is also able to achieve better properties of flame retardant, high temperature resistance and high thermal insulation at extreme temperatures.

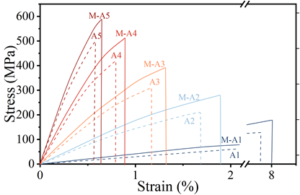

Firstly, the tensile properties of five prefabricated specimens were analyzed, where “M” refers to the modified prefabricated specimens, and the stress-strain curves are shown in Figure 6. It can be seen that the stresses before and after modification gradually increase with the increase of CF content in the composites, and the stresses of multiscale modification are higher than those of unmodified composites, and the stress of M-A5 can reach up to 585.6 MPa. The strains of composites decrease abruptly after the addition of carbon fibers, and the destructive strains of A1 and M-A1 have good strains of 7.78% and 8.02%, and the maximum strains of mixed composites are only 1.0%, and the maximum strains of M-A1 are only 1.0%, and the maximum strains of M-A5 are only 1.0%. A1 and M-A1 have good destructive strains of 7.78% and 8.02%, respectively, and the maximum strain of the hybrid composite is only 1.88% (M-A2). The destructive strains of both A4 and A5 specimens before and after modification were less than 1%. The conclusion shows that the addition of CF fibers in ANF/PBO hybrid composites, although it can increase the elongation at break of the composites, has little effect on the high stiffness and poor toughness of carbon fibers.

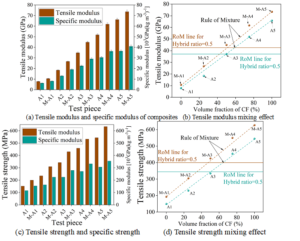

Immediately after that, the tensile modulus, specific modulus, tensile strength, specific strength of CF-ANF-PBO composites and their mixing effects were characterized as shown in Figure 7. Where, Figure 7(a) shows the tensile modulus and specific modulus of the composites and Figure 7(c) shows the tensile strength and specific strength. It can be seen that the tensile modulus, specific modulus, tensile strength and specific strength increase with the increase of carbon fiber content, and the tensile modulus and strength of the A5 specimen are the highest in unmodified with 68.81 GPa and 543.02 MPa, respectively.The tensile modulus and tensile strength of the multiscale modified CF-reinforced composite (M-A5) are the highest in the overall with 73.52 GPa and 636.82 MPa.The tensile modulus and tensile strength of the composites treated with the same multiscale modification showed a similar enhancement compared to the unmodified composites.

The tensile properties of CF-ANF-PBO composites deviating from the law of hybridization (RoH) are shown in Figures (b) and (d). The unmodified composites all exhibit negative hybridization effects and only a slight positive hybridization effect, which is mainly attributed to the large proportion of high-strength CF in the composites. The tensile properties of the composites prepared with the same hybrid structure type after the surface multiscale modification of the hybrid fibers are significantly improved, and thus the tensile modulus and strength show a better positive hybrid effect.

In order to study the low-velocity impact response of CF-ANF-PBO composites, low-velocity impact tests were conducted on some composites in the previous paper to investigate the effects of impact energy and composite structure on impact properties. The impact force-time curve can visualize, when the external impact force acts on the CF-ANF-PBO composites, the form of the impact force in the process and the response of the composites to the impact force. To a certain extent, it can reflect the performance advantages and disadvantages of the composite material to resist the impact, through the analysis of the impact force-time curve, combined with the structural characteristics of the composite material, it can be interpreted for the impact resistance of the composite material.

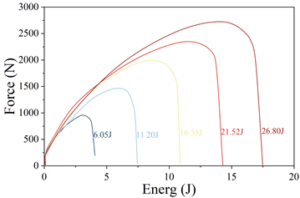

The impact force-time curve of CF-ANF-PBO composites is shown in Figure 8, and it can be seen that when the impact energy is small, the curve is relatively flat, and with the gradual increase of the impact energy from 6.05 J to 26.80 J, the curve becomes steeper gradually, and the curve becomes narrower and taller from flat width. From the point of view of the duration of the impact force, with the increase of the impact energy, the duration of the impact force is gradually reduced, and gradually shifted to the short time zone. From the peak value of the impact force, with the increase of the impact energy, the peak value of the impact force gradually increases, and the peak position is shifted to the direction of shorter action time. Its role can be characterized as follows: with the increase of impact energy, the contact time of the impact head on the composite material is shortened, the impact force is increased, and the deformation speed of the composite material is accelerated.

In order to study the relationship between impact force and impact energy of CF-ANF-PBO composites during the impact process, the impact force-energy curves of the specimens are shown in Figure 9. Before the impact force appears to decay, the slope of the impact force-energy curves under different impact energies is basically the same, basically overlapping as a line, when the impact force begins to decay, the trend of several curves is also basically the same, and the slope decreases gradually, and when the slope decreases to 0, that is, the curve reaches the peak, the curve will appear to decline rapidly, which shows that the trend of the change of the impact force and the impact energy has nothing to do with the size of the impact energy This shows that the trend of impact force and impact energy has nothing to do with the size of impact energy, but is a characteristic of the material itself.

In this paper, in order to improve the toughness of the fiber fabric material, the maximum range of a variety of fibers mixed weaving, so that the resulting super hybrid composites, both with the high strength, high modulus and excellent fatigue properties of aramid fibers, but also the toughness of PBO fibers. Carbon fiber materials are used as modified materials to improve the properties of composites such as flame retardant, high temperature resistance, high thermal insulation, etc., and the super hybrid composites are obtained by RTM molding process. Finally, the cross-section morphology observation and mechanical properties) tests were conducted closely around the super hybrid composites to explore the damage modes and failure mechanisms under different mechanical properties from the macro- and microscopic morphology. The chemical structure analysis reveals that the CF-ANF-PBO composites are purely physically bonded with no new characteristic peaks appearing during the preparation process. Meanwhile, the composites have good thermal stability at the working temperature. At extreme temperatures, it is still enough to achieve better properties such as flame retardant, high temperature resistance and high thermal insulation. The unmodified composites all showed negative mixing effects and only slight positive mixing effects. After multiscale modification, the tensile properties of the prepared composites with the same type of hybrid structure type were significantly improved, so the tensile modulus and strength showed better positive hybridization effect.