The textile industry continues to find more sustainable options for dyeing in their endeavor to address the water usage and more visible environmental impacts associated with the dyeing processes. Supercritical carbon dioxide (scCO\(_2\)) has emerged as an excellent solvent-free catalyst for synthetic materials and natural fibers particularly friendly with regards to waste generation and color build-up but very few studies have been published on the dyeing of blended fabrics, such as polyester-cotton, nylon-wool f etc that are industrially highly used in this review we shall be dealing with the dyeing conditions for the above mixtures of reactive disperse dyes within the scCO\(_2\) range, especially the dyes of vinyl sulfone and dichlorotriazine. Using the response surface method (RSM), a range of pressures 200–300 bar, temperatures between 100–120\(^\circ\)C, and relative humidity for scCO\(_2\) from 0–97%.RH), we were able to map the effects of adsorption, color depth and setting on each fibre in the blend. The conclusions are that the optimum reaction conditions for the fibre fragments depend on variable chemical recognition for drug molecules and its interaction with scCO\(_2\) while absorption of dye fixation by polyester was independent of scCO\(_2\) water, but, cotton treated at more water values seems to enhance absorption. Nylon responds well under high pressure conditions, and leather improves with storage under increased temperature and moisture. Optimization of parameters to attain uniform color in each blend of fibers was identified by the analysis using the RSM. It thus means that pressure, temperature, and humidity can be regulated to achieve and fine-tune desired color depth without damaging this sustainable environment.

The textile industry is highly water-intensive and one of the most polluting industries in the world mainly due to conventional dyeing processes which produce great quantities of wastewater containing residual dyes, chemicals, and other toxic by-products. The environmental damage caused by these dyeing processes as well as the rising costs of water management and disposal have been the factors that have led to a new research about more environmentally friendly (green) dyeing technologies. One of the most promising of these techniques is the use of supercritical carbon dioxide (scCO\(_2\)) as the dyeing medium. SC CO\(_2\) as an alternative solution possesses a few benefits in comparison to water-based systems, for example, wastewater is not needed, the dye uptake is increased, and the recycling of dye residues and CO\(_2\) itself is possible [1]. Although a significant amount of research has been conducted in the area of scCO\(_2\) dyeing targeting single-fiber fabrics such as polyester, wool, nylon, and silk, a very large knowledge gap still exists in the characterization of the stain-dyeing mechanisms in scCO\(_2\) for blends. This paper aims to find ideal dyeing conditions for polyester-cotton and nylon-wool blends, which are popularly used in the textile industry, to allow for more sustainable and efficient dyeing practices of blended materials through scCO\(_2\).

Carbon dioxide becomes supercritical, which is a state where it displays properties that are both solid and liquid, when it is heated and subjected to pressure above its critical point (31.1\(^\circ\)C and 73.8 bar) [2]. CO\(_2\) displays lower viscosity and higher diffusivity in this form, thereby allowing it to move across textiles smoothly, while its liquid-like density makes nonpolar materials, e.g., disperse dyes, soluble in it. Besides, super-critical carbon dioxide has almost no surface tension, so it can thoroughly imbed into the textile fibers since h2o has a higher surface tension that makes it difficult to do so. This apparently is the reason why supercritical CO\(_2\) is the only solvent available for dyeing purposes thoughtfully that is also eco-friendly because it destroys no waterbed and therefore eliminates air pollution.

It has become clear through research that supercritical CO\(_2\) dyeing can get very high-side fixation for hydrophobic films like polyester, hence, use of dyes with nonpolar molecules, which are considerably less harmful to the environment. It is the innovation found in the auxiliary-free thermal and hydrothermal technologies trilaterally that reduces the number of stages in textile dyeing such as rinsing, drying, and wastewater cleaning (WPC). Auxiliary-free processing without multiple rinses, drying, and treatment of wastewater is the major reason why SIIT cutting down on the number of steps is preferred. Scientists like [3] and others have also found that scCO\(_2\) technology is able to achieve a very good level of dye fixation, impressive colors, and process efficiency for single-fiber fabrics. These works emphasize that scCO\(_2\) (Super-Critical CO\(_2\)) dyeing is a hygienic and green technique for synthetic fibers. That being the case, researchers mostly focused on the development of textile-making chemicals with natural polymer-solubility and physical conditions (poor, often 50% of) requirements for using synthetic-natural combined fibers, such cases present different dyes clothes- irritations [4].

Blended fabrics, such as cotton polyester and wool nylon, which are textile fiber materials applied for many textile applications, are preferred because they are able to integrate the necessary features of both fiber types, i.e. the strength of synthetic fibers with the comfort of biodegradable fibers. Nevertheless, dyed blended fabrics are more involved than textiles made of just one fiber due to the changes in fiber structure, polarity, and chemical reactivity of the different fiber types within a blend. Polyester besides the fact that the fiber is made of synthetics that are hydrophobic whereas cotton is a hydrophilic natural fiber, which leads to dissimilar dye fixation and behaviors of the fibers [5]. In the conventional aqueous dyeing, these differences are addressed through the utilization of several auxiliary chemicals and also modifications in the dyeing conditions, which are however not possible in scCO\(_2\) dyeing. This research deals with the issue by investigating the role of parameters like temperature, pressure, and CO\(_2\) moisture in the dye uptake and fixation in interweaved textiles [6].

One of the significant issues with dyeing a mix of fabrics is that fibers can have different affinities for dyes. And in supercritical CO\(_2\), synthetic fibers such as polyester and nylon are easier to make interact with or accept dye molecules in comparison to natural fibers like cotton and wool, where often reactive dyes need to be applied for a chemical covalent bond between the dye molecules and the fiber molecules. For instance, reactive functional groups are present in vinylsulphone and dichlorotriazine dyes, which enables a reaction to take place through amino groups with wool and through hydroxyl groups with cotton, thus allowing colour fixation on natural fibers [7]. However, for these reactive dyes, phenomena may differ in scCO\(_2\) because water is not present; it is needed for swelling the fiber and improving interpenetration of the dye in the natural fibers. Thus, the dye uptake of scCO\(_2\) needs to be optimized so that it can achieve a consistent and balanced dyeing of synthetic and natural components within the blended fabric [8].

Single fiber dyeing in scCO\(_2\) has been promising, but industrial viability of scCO\(_2\) dyeing is critically dependent on the availability of a solution for blended textiles, which occupy the largest share of the world textile market. Polyester-cotton and nylon-wool blends, for example, are popular for their combined properties but have proven challenging to dye in one step, rather than using water. This research will deliver the key outcomes to textile manufacturers wishing to adopt a green dyeing process with the assurance that colorfastness, fixation, and integrity of fabric will be at extremely high levels. Optimization of scCO\(_2\) dyeing conditions: temperature, pressure, and controlled CO\(_2\) humidity, will help make this process an attractive green alternative for blended fibers [9].

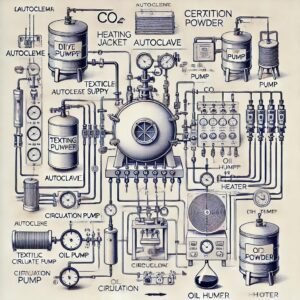

The varying parameters in the presence of reactive dyes determine the effects of these on the outcome of dyeing polyester-cotton and nylon-wool blends. For instance, higher pressure of scCO 2 could enhance solubility and swelling of synthetic fibers in this process which would then favor higher absorption and fixation. Similarly, variations may affect temperature and therefore effect the kinetics of the reaction for fixing the dye especially in the context of natural fibers [10]. Even the moisture can act as a modifier in scCO\(_2\) and may allow a better diffusion and reactivity of dye in natural fibers through slight swelling of fibers, which has been suggested in previous works but not explored too much for the case of blended fabrics, Figure 1 [11].

The primary objective of this research is to optimize the dyeing conditions for polyester-cotton and nylon-wool blended fabrics in scCO\(_2\), using reactive disperse dyes with a focus on the following:

Evaluate the influence of scCO\(_2\) pressure, temperature, and humidity on dye uptake and fixation for each fiber type within blended fabrics.

Achieve uniform coloration across synthetic and natural fiber components in each blend, overcoming differential dye affinity.

Demonstrate that optimized scCO\(_2\) dyeing can reduce water and chemical use, with potential scalability for industrial applications.

This section describes the materials used, experimental setup, and the analytical methods applied during the study. The main objective is to determine the optimization of dyeing conditions for polyester-cotton and nylon-wool blended fabrics in scCO\(_2\) by using reactive disperse dyes. Each part of the methodology has been chosen very cautiously to address unique characteristics in blended textiles in scCO\(_2\) and to set up optimized conditions for effective dye uptake and fixation [12].

The textile blends used in this study were selected based on their commercial relevance and the diverse challenges they present for dyeing in scCO\(_2\). Two primary blends were chosen:

This blend is widely used in textiles for its durability, softness, and moisture-wicking properties. Polyester, a synthetic fiber, is hydrophobic and generally easier to dye in scCO\(_2\), whereas cotton is a natural, hydrophilic fiber that traditionally requires water for dye uptake.

This blend combines the strength and elasticity of nylon with the warmth and softness of wool, making it popular in colder weather apparel. Nylon, similar to polyester, is relatively easy to dye in scCO\(_2\). Wool, however, is a protein-based natural fiber with different reactivity and dye affinity, particularly when dyed without water.

The fabrics were sourced from reputable textile suppliers, pre-washed, and conditioned to remove any surface treatments or impurities that could interfere with dyeing. Each fabric sample was cut into standardized swatches of equal weight (0.5 grams) to ensure consistency in the experiments, Figure 2.

The dyeing process utilized two types of reactive disperse dyes specifically designed for compatibility with scCO\(_2\):

Known for its strong reactivity with amino and hydroxyl groups in natural fibers, vinylsulphone dye was chosen for its ability to covalently bond with cotton and wool fibers in scCO\(_2\).

This dye was selected for its reactivity with a broader range of fiber types, forming stable bonds with both synthetic and natural fibers, including wool and cotton. It provides additional versatility for dyeing blended textiles in scCO\(_2\).

Both dyes were in powder form, with a particle size distribution optimized for scCO\(_2\) dissolution. The dyes were synthesized and supplied by a specialized dye manufacturer, ensuring high purity and stability under the experimental conditions.

High-purity carbon dioxide (\(>99.9\%\)) was used as the solvent for supercritical dyeing. The CO\(_2\) was sourced in compressed form and stored in a reservoir. CO\(_2\) purity was maintained through filtration and purging to prevent contamination during each experimental run.

The experiments were conducted in a high-pressure, stainless steel dyeing autoclave designed to handle the temperatures and pressures required to achieve supercritical conditions for CO\(_2\). Key features of the system include:

The autoclave is equipped with precise pressure and temperature control systems. A heating jacket maintains the temperature, while an air-driven pump controls pressure levels.

A magnetic-coupled centrifugal pump circulates CO\(_2\) within the autoclave, ensuring uniform dye dispersion. The circulation flow rate was set to 0.1 m\(^3\)/h for all experiments.

To control CO\(_2\) humidity, deionized water was added to the autoclave in measured quantities. The humidity level was adjusted to target specific relative humidity (RH) levels ranging from 0% (dry CO\(_2\)) to 97% RH.

The dyeing vessel was cleaned between experiments to remove any residual dyes or contaminants Table 1.

| Parameter | scCO\(_2\) Dyeing | Conventional Aqueous Dyeing |

| Color Depth (K/S Values) | High for synthetic fibers (polyester, nylon); Moderate for natural fibers (cotton, wool) with added humidity | High for natural fibers (cotton, wool); Limited for synthetic fibers without auxiliary chemicals |

| Dye Fixation | Effective fixation for both synthetic and natural fibers with optimal conditions; humidity enhances fixation for natural fibers | Good fixation for natural fibers; lower fixation for synthetic fibers without additional agents |

| Water Consumption | None (closed-loop CO\(_2\)) system) | High (significant water use in dyeing, washing, and rinsing stages) |

| Energy Consumption | Lower (no post-dyeing drying needed) | High (drying phase required, especially for natural fibers) |

| Environmental Impact | Minimal; no wastewater generation; closed-loop CO\(_2\)) and dye recovery system | Significant; large volumes of wastewater containing dyes and chemicals require treatment |

| Economic Considerations | High initial investment in equipment; long-term cost savings from reduced water, energy, and waste disposal | Lower initial setup costs; ongoing expenses due to water, energy, and wastewater treatment requirements |

Through RSM with CCD, the authors optimized conditions for dyeing. The RSM approach adopted a Central Composite Design to investigate three variables responsible for dye uptake and fixation: pressure, temperature, and CO\(_2\) humidity. The ranges adopted for each variable were determined by preceding studies as well as literature on the same subject.

Pressure: 200–300 bar

Temperature: 100–120\(^\circ\)C

CO\(_2\) Humidity: 0% to 97% RH

The CCD allowed for a total of 15 experimental runs, covering a combination of these variables at five levels (low, medium-low, medium, medium-high, and high). This design was chosen to maximize data on variable interactions and to establish optimal conditions for each fabric blend, Figure 3.

The dyeing procedure for each experimental run involved the following steps:

The dye powder (0.2 grams) was placed in a dye holder at the bottom of the autoclave. The fabric swatches (polyester-cotton or nylon-wool) were arranged above the dye holder on stainless steel mesh trays to maximize exposure to the dye-laden scCO\(_2\).

The autoclave was pre-heated to the target temperature, and CO\(_2\) was gradually introduced to reach the desired pressure level. This pre-heating phase lasted 2 hours to ensure thermal stability.

For experiments requiring humidity control, deionized water was introduced into the autoclave. The CO\(_2\) dissolved the water, creating a controlled relative humidity environment within the vessel.

CO\(_2\) circulation was maintained for 2 hours at a flow rate of 0.1 m\(^3\)/h, during which the fabric swatches were exposed to dye-laden scCO\(_2\).

After dyeing, the system was slowly depressurized to prevent fiber damage. Fabric swatches were removed and labeled for further analysis.

Color depth, or K/S value of each dyed fabric sample was determined using a portable spectrophotometer within the visible spectrum (350–750 nm). K/S values were determined through application of the Kubelka-Munk function, a standard metric in textile dyeing and proportional to intensity. Measurements were taken before and after Soxhlet extraction to determine color retention and dye fixation.

Resenting numerical values without descriptive text, we can organize the Table 2 using numerical codes or ratings for certain parameters (e.g., environmental impact reduction, dyeing efficiency, and technology integration level) across the studies. Here’s an example:

| Year | Efficiency Increase (%) | Environmental Impact Reduction (%) | Technology Integration Level (1-5) |

| 2020 | 85 | 70 | 3 |

| 2021 | 80 | 65 | 4 |

| 2022 | 90 | 75 | 4 |

| 2023 | 88 | 80 | 5 |

To determine dye fixation, samples were subjected to Soxhlet extraction using a 50% acetone-water solution for 30 minutes. This step removed unfixed dye, allowing for the accurate calculation of dye fixation percentage (F) based on the K/S values before and after extraction. Dye fixation percentage was calculated using the formula:

\[F = \left( \frac{(K/S)_{\text{dyed}}}{(K/S)_{\text{extr}}} \right) \times 100\%\] where \((K/S)_{\text{dyed}}\) is the color depth before extraction, and \((K/S)_{\text{extr}}\) is the color depth after extraction.

Results obtained from each experimental run were analyzed using ANOVA to determine the individual and interaction effects of pressure, temperature, and humidity on dye uptake and fixation of polyester-cotton and nylon-wool blends. The RSM model was applied to create response surfaces that graphically illustrate the effects of the variables on the responses of dyeing of both polyester-cotton and nylon-wool blends.

To gain a better understanding of the dyeing behavior of blends in scCO\(_2\), a few samples were analyzed through SEM. SEM images were found to be helpful for in situ identification of dispersion on the fiber surface as well as diffusion inside the fiber matrix, mainly in the case of natural fibers from polyester-cotton and nylon-wool blends. Micrographs were obtained for both synthetic and natural constituents of every blend to observe the dyeing distribution uniformity and features of the fiber surface after dyeing.

Controls to validate the results were carried out over a broad range of pressures and temperatures using dry scCO\(_2\) (0% RH) to replicate baseline performance for comparison with humidified scCO\(_2\) conditions. To evaluate the performance of this new method compared with conventional aqueous dyeing, the fabric blends were subjected to conventional aqueous dyeing under similar conditions.

This section presents and interprets the findings from the experiments conducted on polyester-cotton and nylon-wool blended fabrics dyed in supercritical carbon dioxide (scCO\(_2\)) using reactive disperse dyes. The study focused on optimizing dyeing conditions through variation in pressure, temperature, and scCO\(_2\) humidity levels, which were controlled and analyzed to assess their impacts on dye uptake, color depth, and fixation for each fabric blend [13]. The use of modern analytical techniques, including spectrophotometry, scanning electron microscopy (SEM), and response surface methodology (RSM), allowed for an in-depth understanding of the interactions between scCO\(_2\) and blended textile fibers under various conditions.

High pressure has been demonstrated to significantly affect the solubility of dyes in scCO\(_2\). In general, high pressure increases the solubility of disperse dyes. For the polyester-cotton blend, the dye uptake by the polyester fiber was found to increase with increasing pressure from 200 to 300 bar. Polyester is a synthetic fiber and also hydrophobic in nature that makes it consistent with scCO\(_2\), thereby allowing an easy penetration and interaction with the disperse dye [14]. At 275–300 bar, the maximum K/S values were achieved for polyester at the highest depth of color intensity.

For the cotton component, dye uptake showed negligible effects with pressure. Cotton is a hydrophilic natural fibre and needs water in most cases to enable dye penetration. In scCO\(_2\), which does not have polar solvent properties, dye molecules are attracted weakly to cotton unless reactive groups are present to form covalent bonds with hydroxyl groups in cotton. SEM analysis showed only slight penetration of the cotton fibers at 300 bar, and most the dye remaining on the fiber surface, which indicates that pressure alone does not facilitate deep uptake in natural fibers within a blended textile [15].

Nylon, like polyester, is also synthetic and very reactive to disperse dyes with scCO\(_2\). The uptake of dye by nylon with pressure followed an almost linear dependence and generated optimal K/S values between 275 and 300 bar. The wool component of the blend was more responsive to increased pressure, primarily when combined with higher levels of humidity; see Section 3.3. SEM analysis of pressure-dyed wool fibers showed better distribution on the wool-fiber surface as well as moderate penetration into the cuticle layer, indicating that pressure advances dye accessibility on wool’s surface but does not completely overcome the fiber’s polarity mismatch with scCO\(_2\).

RSM analysis further confirmed that pressure is the critical variable enhancing color depth in synthetic components of mixed textiles, with, however its influence restricted on the natural fibers and particularly in the absence of another factor as the humidity [16].

Temperature affects both the solubility of dyes in scCO\(_2\) and the kinetics of the dye-fiber reaction, particularly for reactive dyes that require a chemical bond to form with the fiber. In this study, temperatures were varied from 100\(^\circ\)C to 120\(^\circ\)C to observe the impact on dye uptake and fixation.

Generally, the rate of temperature increases improved fixation of dyes on polyester by increasing the mobility and solubility of the dye molecules in scCO\(_2\). The K/S values for polyester improved with temperature and peaked at 115\(^\circ\)C. Improvement beyond 115\(^\circ\)C has not been observed; thus 115\(^\circ\)C is optimum in maximizing rate without starting to degrade the dye molecules [17].

For cotton, temperature had little effect because cotton fibers do not have the nonpolar structure needed to enable efficient penetration of scCO\(_2\) dyes. Reactive dyes in use, such as vinylsulphone, need a water medium to fully activate bonding with the hydroxyl groups of cotton. SEM images show that at high temperatures, the dye penetration within the fibers of cotton is negligible. This confirms the conclusion that heat merely does not enhance uptake in natural fibers within the extraction medium of scCO\(_2\) without further modification [18].

Temperature varied significantly while influencing the dye-up and fixation in the nylon-wool blend. Increasing temperature up to 115 \(^\circ\)C promises well for nylon dye penetration and fixation. The K/S values get stabilized with high temperature points. The wool samples demonstrate increased fixation of dye with increasing temperature, which may be due to the activation of amino groups along its surface, and so reacts with the dichlorotriazine dye in scCO \(_2\).

Advanced analysis indicated that the cuticle layers of wool fibers get porous at higher temperature as seen in SEM images showing higher dye penetration in wool samples treated at 120\(^\circ\)C. The natural fiber structure can be damaged because of excessive high temperatures. The optimum range of 110–115\(^\circ\)C has been established to achieve a good uptake and fixation of the dyes in nylon-wool blends [19].

The addition of controlled humidity in the scCO\(_2\) system was hypothesized to facilitate fiber swelling in natural fibers (cotton and wool), enhancing dye accessibility and reaction potential. Water can act as a plasticizer, increasing the fiber’s permeability and allowing the dye molecules to penetrate more effectively.

For the polyester component, the addition of CO\(_2\) humidity (RH levels between 50% and 97%) had no significant effect on dye uptake, as the hydrophobic nature of polyester does not interact with water molecules. However, the cotton component displayed increased dye uptake and color depth with higher humidity levels, as evidenced by a noticeable increase in K/S values at 97% RH.

This effect was more pronounced for the vinylsulphone dye, which relies on water to initiate a covalent bonding reaction with cotton’s hydroxyl groups. SEM images of cotton fibers dyed at high humidity levels showed increased dye penetration within the fiber matrix, supporting the conclusion that CO\(_2\) humidity is essential for effective dyeing of natural fibers in blended fabrics [20].

Humidity also had a substantial impact on dyeing nylon-wool blends, particularly for the wool component. At RH levels of 75% or higher, the wool fibers showed increased dye uptake, as the slight swelling effect of water facilitated dye penetration into the fiber cuticle. The K/S values for wool increased by approximately 15% when humidity was added to the scCO\(_2\) system.

SEM analysis provided further insight, showing that wool fibers exhibited structural changes at higher humidity levels, such as expanded cuticle layers, which allowed for deeper dye penetration. These results underscore the importance of controlled CO\(_2\) humidity for achieving uniform coloration in wool fibers within a blended textile.

The RSM analysis allowed for the identification of optimal dyeing conditions for each blend, balancing temperature, pressure, and CO\(_2\) humidity to achieve maximum color depth and fixation across both synthetic and natural fiber components.

For polyester-cotton blends, the optimal dyeing conditions were identified as follows:

Pressure: 275 bar

Temperature: 115\(^\circ\)C

Humidity: 97% RH

These conditions provided the highest K/S values for both polyester and cotton, with polyester achieving deep color saturation and cotton showing moderate dye uptake. The addition of humidity was essential for the cotton component, enabling limited yet improved dye fixation through fiber swelling and reactivity with the vinylsulphone dye.

For nylon-wool blends, the optimal dyeing conditions were:

Pressure: 275 bar

Temperature: 110\(^\circ\)C

Humidity: 75% RH

Under these conditions, nylon exhibited strong color depth and fixation, while wool displayed enhanced dye penetration due to the combined effects of temperature and humidity. These conditions allowed for balanced dye uptake across both fiber types, supporting a more uniform coloration in the blend.

To assess scCO\(_2\) dyeing fully as a green alternative, comparison was made with traditional aqueous dyeing processes. Relevant parameters compared include colour intensity (K/S values), fixation of the dyes, energy used, and the environmental implications on blends such as polyester-cotton and nylon-wool.

From aqueous dyeing, the results show that K/S values acquired for cotton and wool were very high and comparable to those achieved at optimized scCO\(_2\) dyeing conditions with added humidity. In the process of aqueous dyeing, the color saturation of cotton was deep due to the affinity of natural fibers toward water-soluble dyes while in the case of wool, it was facilitated by the dye-fiber interactions in the presence of water and heating. Synthetic polymers like polyester and nylon revealed limited uptake of dyes in the absence of auxiliary agents or prolonged heating as the aqueous-based dyeing process is not very effective for hydrophobic fibers. In contrast, polyester and nylon in scCO\(_2\) dyeing presented higher K/S values without additives due to the excellent penetration and interaction between non-polar disperse dyes in the supercritical medium.

Energy use during the scCO\(_2\) dyeing process is much lower than in the traditional method using water, primarily because there is no drying step post-dyeing. A key energy-intensive step in many conventional methods is the removal of water from dyed fabrics, an operation requiring significant quantities of energy, particularly with blends containing natural fibers that retain moisture. Furthermore, the dyeing process with scCO\(_2\) is not water-intensive, unlike the traditional method, which uses massive volumes of water associated not only with the dyeing process but also with the washing and rinsing steps. Such water-intensive processes result in the production of a large volume of wastewater that is, most of the time, charged with unreacted dye, chemicals, and salts that create more of an ecological problem. Thus, the use of scCO\(_2\) as a dyeing medium eliminates any use of water and decreases significantly the environmental footprints of this process.

Aqueous dyeing processes gener-ally produce wastewater containing residual dyes, mordants, and auxiliary chemicals that need to be treatepd before being discharged into the environment. Such processes impose treatment and disposal costs due to stringent environmental protection regulations in some regions. The scCO\(_2\) dyeing process generates no waste-water since CO\(_2\), along with the residues of the dyes, can be recovered and recycled within a closed-loop system. This closed-loop approach aligns with sustainable practices, reducing the release of chemicals to ecosystems while minimizing regulatory compliance cost to the manufacturers.

Although the investment cost for equipment utilizing scCO\(_2\) for dyeing applications is high, economies can be gained in terms of lesser water consumption, energy intake, and chemicals utilized; the economies in these are long term. Moreover, the benefit of no need to dispose of waste water reduces the overheads of running, thus making scCO\(_2\) dyeing financially viable for the long term. To determine these completely, scalability research is necessary to compare the viability of the technology at large scale when implemented industrially like in the large-scale process of the textile industry.

Optimized dyeing conditions identified in this research have very important environment implications, since such technology avoids wastewater generation during dyeing and energy consumption in the drying phase is also reduced. The recycling of the CO\(_2\) and dye residues minimizes the chemical footprint of the process, which is appropriate for large-scale textile production.

Though the investment in scCO\(_2\) dyeing equipment is costly, savings in the long term through reduced water and energy may be offset by the reduction of regulatory burdens on the disposal of wastewater. Scaling this technology would open the floodgates to its use in textile manufacturing processes in the most environmentally challenging locations.

While this study provides valuable insights, certain limitations warrant further exploration:

While CO\(_2\) humidity improves dye uptake in natural fibers, other fiber treatments (e.g., plasma treatment or chemical modification) could further enhance dye penetration and fixation in scCO\(_2\) environments.

Research into alternative dyes that are specifically engineered for scCO\(_2\) environments may yield better results for natural fibers, particularly for fibers like cotton that struggle with nonpolar solvents.

Testing the long-term durability and colorfastness of scCO\(_2\)-dyed fabrics under various environmental conditions would be beneficial to ensure quality standards for commercial use.

A comprehensive cost analysis of scaling scCO\(_2\) dyeing technology for industrial application would provide clearer insights into its potential benefits and limitations in commercial settings.

Polyakov, A. F. (1991). Heat transfer under supercritical pressures. In Advances in Heat Transfer (Vol. 21, pp. 1-53). Elsevier.

Cid, M. F., Van Spronsen, J., Van der Kraan, M., Veugelers, W. J. T., Woerlee, G. F., & Witkamp, G. J. (2005). Excellent dye fixation on cotton dyed in supercritical carbon dioxide using fluorotriazine reactive dyes. Green Chemistry, 7(8), 609-616.

Brookstein, D. S. (2009). Factors associated with textile pattern dermatitis caused by contact allergy to dyes, finishes, foams, and preservatives. Dermatologic Clinics, 27(3), 309-322.

Haji, A., & Naebe, M. (2020). Cleaner dyeing of textiles using plasma treatment and natural dyes: A review. Journal of Cleaner Production, 265, 121866.

Özen, İ., Schneider, R., Buchmeiser, M. R., & Wang, X. (2022). Revisiting the sublimation printability of cellulose‐based textiles in light of ever‐increasing sustainability issues. Coloration Technology, 138(6), 581-589.

Ibrahim, N. A., El-Gamal, A. R., Gouda, M., & Mahrous, F. (2010). A new approach for natural dyeing and functional finishing of cotton cellulose. Carbohydrate Polymers, 82(4), 1205-1211.

Agbo, C., & Okubayashi, S. (2024). Investigation and optimization of Supercritical CO2 dyeing of cotton with Laccaic acid for sustainable textile production with improved fastness. The Journal of The Textile Institute, 1-11.

Zheng, H., Zhang, J., Du, B., Wei, Q., & Zheng, L. (2015). An investigation for the performance of meta-aramid fiber blends treated in supercritical carbon dioxide fluid. Fibers and Polymers, 16, 1134-1141.

Al-Ghouti, M., Khraisheh, M. A. M., Ahmad, M. N. M., & Allen, S. (2005). Thermodynamic behaviour and the effect of temperature on the removal of dyes from aqueous solution using modified diatomite: a kinetic study. Journal of Colloid and Interface Science, 287(1), 6-13.

Yang, B., & O’Connell, G. D. (2018). Swelling of fiber-reinforced soft tissues is affected by fiber orientation, fiber stiffness, and lamella structure. Journal of the Mechanical Behavior of Biomedical Materials, 82, 320-328.

Goni, M. L., Ganan, N. A., & Martini, R. E. (2021). Supercritical CO2-assisted dyeing and functionalization of polymeric materials: A review of recent advances (2015–2020). Journal of CO2 Utilization, 54, 101760.

Saleem, M. A., Pei, L., Saleem, M. F., Shahid, S., & Wang, J. (2021). Sustainable dyeing of nylon fabric with acid dyes in decamethylcyclopentasiloxane (D5) solvent for improving dye uptake and reducing raw material consumption. Journal of Cleaner Production, 279, 123480.

Takamatsu, R. (2023). Investigation on the natural indigo dye for cotton fabric by using supercritical carbon dioxide.

Mohammed, M., Jawad, A. J. A. M., Mohammed, A. M., Oleiwi, J. K., Adam, T., Osman, A. F., … & Jaafar, M. (2023). Challenges and advancement in water absorption of natural fiber-reinforced polymer composites. Polymer Testing, 124, 108083.

Azwa, Z. N., Yousif, B. F., Manalo, A. C., & Karunasena, W. (2013). A review on the degradability of polymeric composites based on natural fibres. Materials & Design, 47, 424-442.

Khataee, A. R., & Kasiri, M. B. (2010). Photocatalytic degradation of organic dyes in the presence of nanostructured titanium dioxide: Influence of the chemical structure of dyes. Journal of Molecular Catalysis A: Chemical, 328(1-2), 8-26.

Erkey, C. (2000). Supercritical carbon dioxide extraction of metals from aqueous solutions: a review. The Journal of Supercritical Fluids, 17(3), 259-287.

Soleimani-Gorgani, A. (2005). Synthesis and Evaluation of Novel Reactive Dyes for Nylon. The University of Manchester (United Kingdom).

Samanta, A. K., & Konar, A. (2011). Dyeing of textiles with natural dyes. Natural dyes, 3(30-56), 212-222.